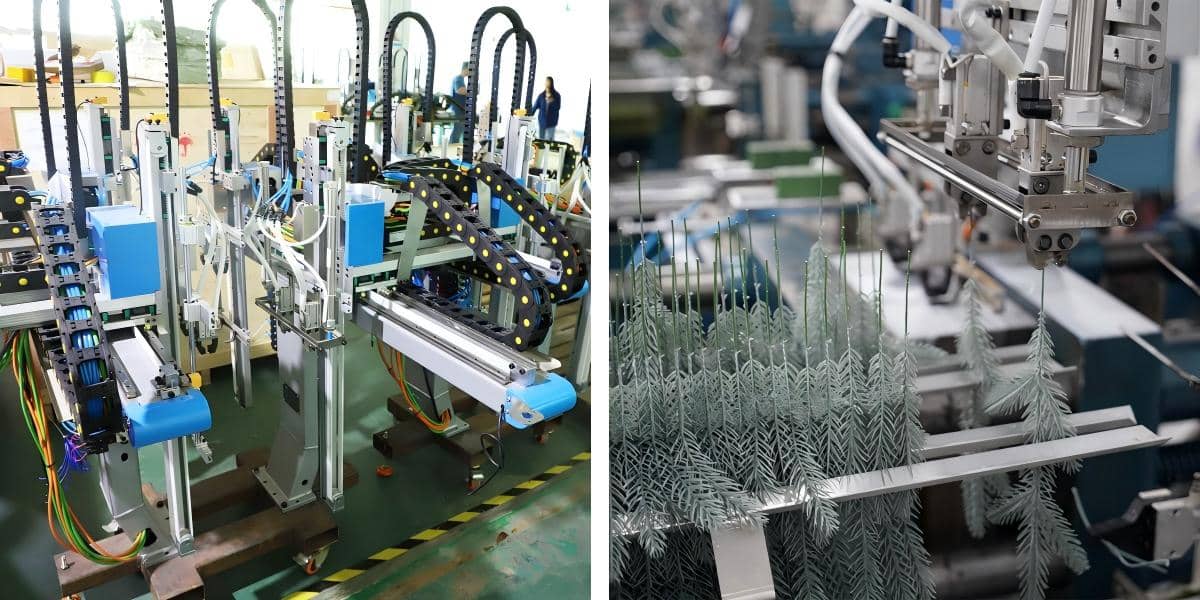

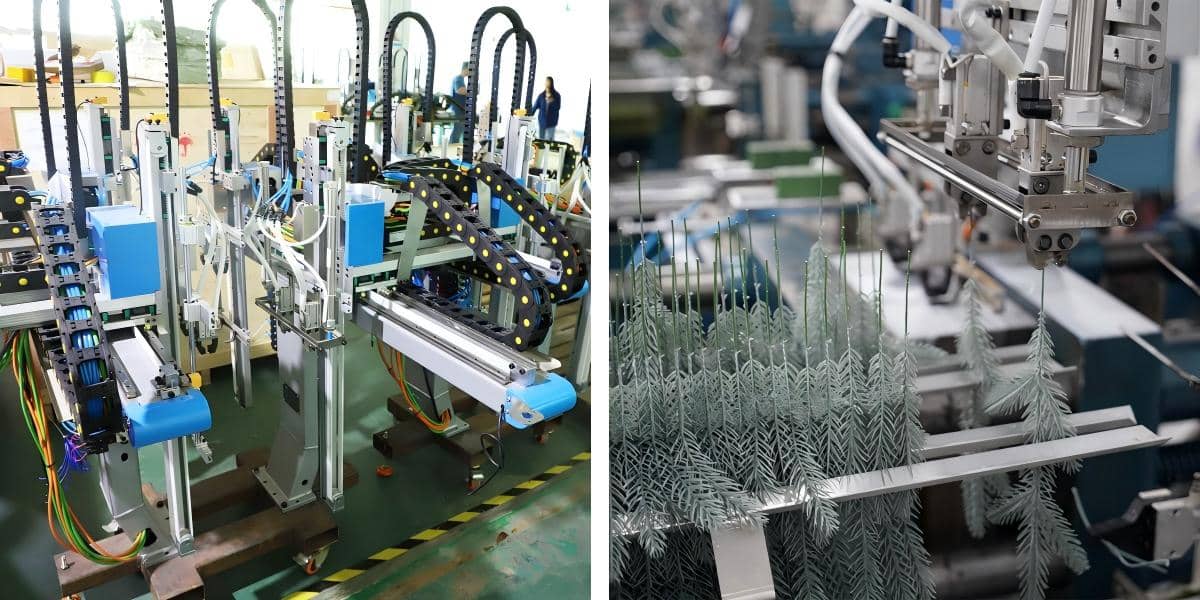

Robɔt nsa no yɛ mfiri a ɛho hia sen biara wɔ injection molding nhyehyɛe no nyinaa mu. Bere a wɔreyɛ no, robɔt nsa no yi plastic a wɔde kata so no fi afiri a wɔde twitwiw nneɛma a wɔde yɛ aduru no mu no mu, de gu injection mold no mu, twɛn ma PE plastic a ɛyɛ hyew no ma ɛyɛ den ma ɛyɛ tebea pɔtee bi, na afei woyi fi hɔ na wɔde gu adekoradan bi so wɔ nkyɛn ma adwumayɛfo boaboa ano.

Robɔt nsa a wɔde di dwuma .

Robɔt nsa a ɛwɔ saa afiri yi mu no kɛse sua koraa, na etumi fa nhaban nketenkete a wɔde PE injection ayɛ no nhwɛsode nkutoo. Electricity na ɛma robɔt nsa no yɛ adwuma nanso ɛyɛ adwuma wɔ mframa mu bere a ɛreyɛ adwuma no. Afiri no nyinaa yɛ adwuma sɛnea nhyehyɛe a wɔadi kan ayɛ ho nhyehyɛe te.

Robot Arm parameter .

Nipadua no trɛw . |

1480mm . |

Nipadua no sorokɔ . |

1500mm . |

Ma nsusuwso no nkɔ fam sen nea wɔde si dan no mu no . |

150mm . |

Ma nsusuwso no nkɔ soro nsen wimhyɛn a wɔde si hɔ no . |

150mm . |

Wire tenten a ɛsen biara . |

350mm . |

Wire feeder type . |

Ɔkwan a ɛda ntam no yɛ nea wotumi sesa, Type A . |

| Wire feeder a wɔde si hɔ no yɛ . |

Hanging . |

| Nnipa dodow a wɔtɔn nneɛma . |

1 anaa 2 . |

| Wire no kɛse . |

0.9mm-1.4mm . |

| Line ntam kwan . |

≥28mm . |

| Ɔkwan a wɔfa so yi nsu fi mu . |

Ɔkwan a wɔfa so yi nsu fi mu . |

| Ɔkwan a wɔfa so yi nsu fi mu . |

Ntrɛwmu a ɛyɛ tẽẽ . |

Mfaso a ɛwɔ robɔt nsa so .

Automation .

Wɔ PE Buronya dua nhaban a wɔyɛ mu no, robɔt nsa na ɛyɛ wɔn asɛyɛde sɛ ɛbɛfa nneɛma, ayɛ nhaban, na wɔde nneɛma a wɔawie ayɛ, na ɛnam so ayɛ adwuma no nyinaa afiri mu.

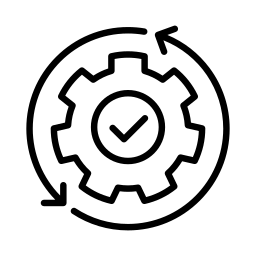

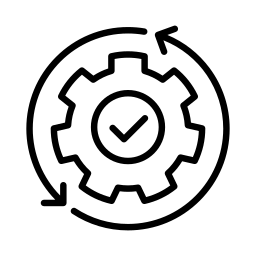

Nneɛma a wɔyɛ no yiye .

Efi waya a wɔde plastic adura ho a wɔboaboa ano so kosi PE nhaban a wɔawie no a wɔde gu ade no so no so no, robɔt nsa no wie kyinhyia no nyinaa wɔ nea ennu sikɔne 10 mu, na ɛma nneɛma a wɔyɛ no tu mpɔn kɛse.

Ma ɛnyɛ mmerɛw sɛ wɔbɛyɛ nneɛma a wɔyɛ no .

Robɔt nsa asi adwumayɛfo ananmu wɔ nhaban a wɔde PE injection ayɛ no mu, na wɔawie mfinimfini anammɔn dodow no ara na wɔahu PE ahaban a wɔaka abom a wɔyɛ no.

Nneɛma a wɔde kyekyere nneɛma ho ne nea wɔde mena .

Nneɛma a wɔde kyekyere nneɛma ho .

Mpɛn pii no, yɛde nnaka a wɔde nnua ayɛ na ɛhyɛ mfiri no mu. Yɛde pallets gu crates no ase ma ɛnyɛ den sɛ wobɛfa so, na yɛde nnua a wɔde ayɛ afiri no hyɛ ase no mu den de hyɛ afiri no mu den. Yɛsan nso de afã horow bi a ɛnyɛ den sɛ ɛbɛsɛe wɔ nnaka no mu ka ho de hwɛ hu sɛ wɔde mfiri bedi dwuma bere tenten.Nokwarem no, sɛ wowɔ ahwehwɛde soronko a ɛfa nneɛma a wɔde kyekyere nneɛma ho a, yebetumi nso ayɛ nneɛma a wɔde kyekyere nneɛma ho ma wo.

Suhyɛn so dwumadie

Afiri no boa mframa ne keteke akwantu nyinaa; Wubetumi apaw ɔkwan a wɔfa so de nneɛma kɔma nkurɔfo a ɛfata w’ahiade yiye. Yɛbɛbɔ adwumayɛbea no amanneɛ sɛ wɔmfi ase nyɛ adwuma bere a wɔasi so dua no. Sɛ wɔwie a, wɔbɛsɔ afiri no ahwɛ, na sɛ wɔsi so dua sɛ ɛyɛ adwuma yie a, wɔbɛhyehyɛ no na wɔde akɔ beaeɛ a wɔakyerɛ no. Sɛ wowɔ mpɔtam hɔ ɔnanmusifoɔ wɔ wo mpɔtam hɔ a, yɛbɛtumi nso de afiri no akɔma wɔn, a wɔbɛdi nneɛma a aka a wɔde bɛmena no ho dwuma.

FAQ .

Dɛn na wɔde robɔt nsa yi di dwuma titiriw?

Wɔayɛ saa robɔt nsa yi ama PE a wɔde ayɛ Buronya dua nhaban a ɛyɛ adwuma wɔ ɔkwan a ɛyɛ adwuma so. Wɔde di dwuma titiriw de yi plastic nhaban a wɔawie fi afiri a wɔde twitwiw nneɛma mu no mu na wɔde gu nneɛma a wɔboaboa ano so, na ɛtew nsa a wɔde di dwuma so na ɛma nneɛma a wɔyɛ no tu mpɔn.

Nneɛma ne nneɛma bɛn na robɔt nsa betumi adi ho dwuma?

Robɔt nsa no fata sɛ wɔde di nneɛma nketenkete a emu yɛ hare a wɔde PE injection ayɛ ho dwuma, titiriw PE Buronya dua nhaban. Wɔayɛ no yiye ama adwuma a wɔyɛ no mpɛn pii a wɔpaw ne beae a wɔyɛ adwuma wɔ mmeae a wɔyɛ nneɛma a ɛyɛ frequency a ɛkorɔn.

So robɔt nsa no yɛ nea ɛyɛ adwuma ankasa koraa?

Aane. Robɔt nsa no yɛ adwuma sɛnea nhyehyɛe a wɔadi kan ayɛ ho nhyehyɛe te. Sɛ wɔde parameters no si hɔ wie a, ebetumi awie picking, transferring, ne placing operations a nsaano dwumadie a ɛsua koraa.

Nsiesiei bɛn na robɔt nsa no hwehwɛ?

Nea ɛka nsiesie a wɔyɛ daa no ho titiriw ne ahotew, mframa a wɔde yɛ adwuma a wɔhwɛ mu, ne hwɛ a wɔhwɛ hu sɛ wɔde srade bɛhyɛ afã horow a ɛkɔ so no mu yiye. Sɛ wosiesie robɔt nsa no yiye a, ebetumi ayɛ adwuma denneennen bere tenten.

So saa robɔt nsa yi betumi ayɛ adwuma wɔ mfiri ahorow a wɔde injection ayɛ mu?

Aane. Wobetumi de robɔt nsa no ayɛ biako ne PE injection molding mfiri dodow no ara a ɛyɛ gyinapɛn. Wobetumi asiesie instɔlehyɛn sorokɔ ne adwumayɛ kwan sɛnea nsusuwso gyinabea ne mfiri nhyehyɛe te.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá