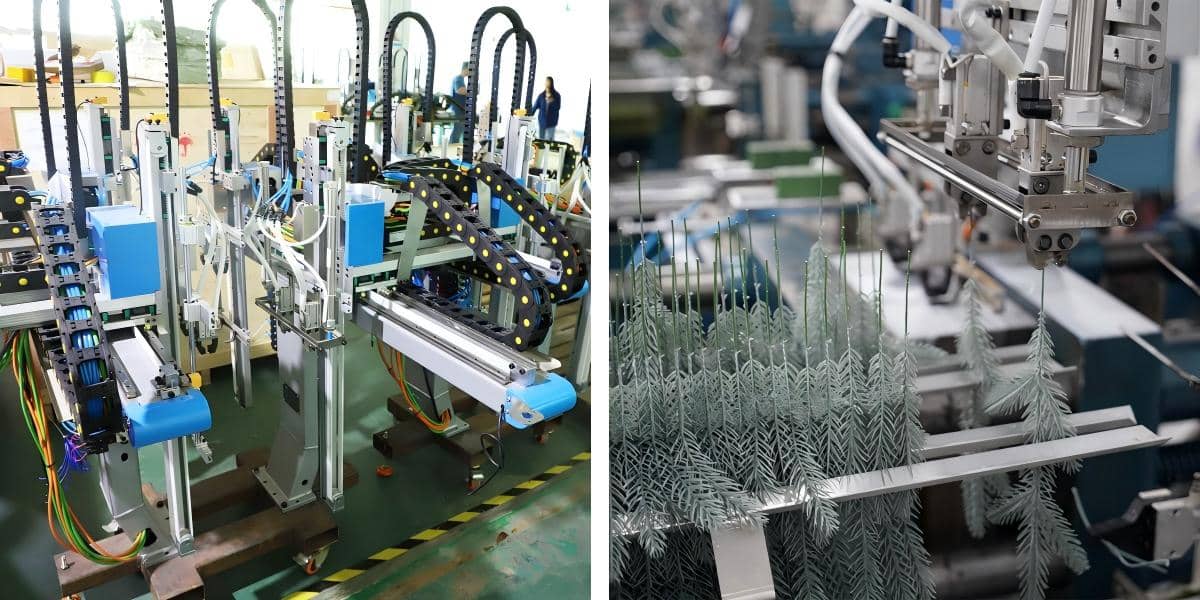

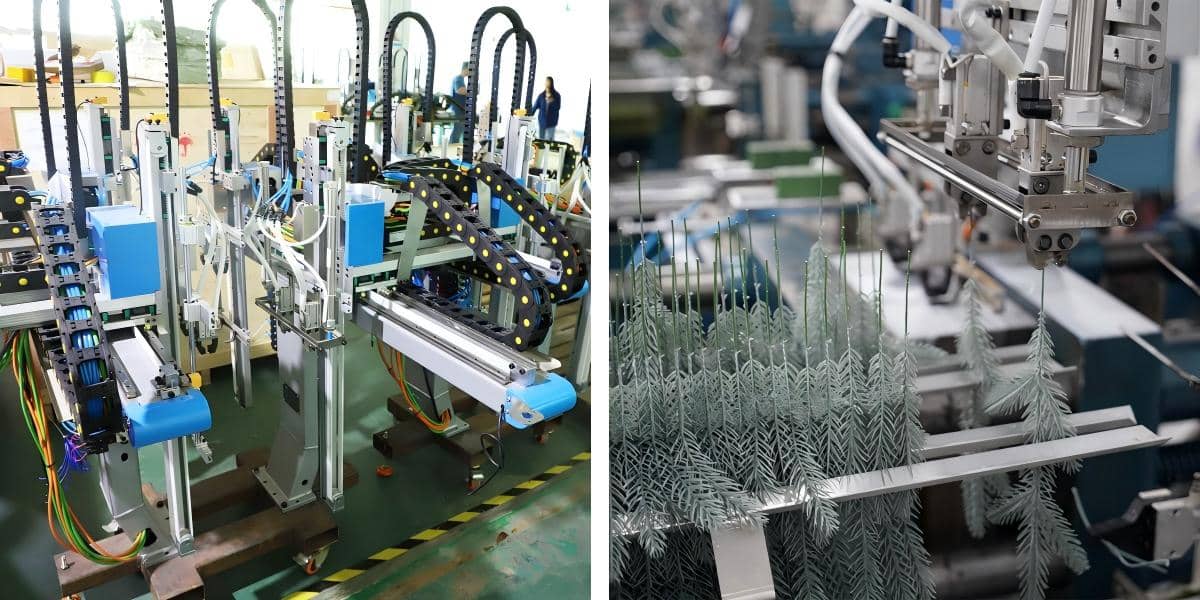

The robot arm is the most important piece of machinery in the entire injection molding system automation. During production, the robot arm removes the plastic coating line from the injection molding machine's groove, places it into the injection mold, waits for the hot-melt PE plastic to solidify into a specific shape, and then removes it and places it on a shelf on the side for workers to collect.

Application Of Robot Arm

The robot arm of this machine is relatively small in size, capable only of picking up small samples of PE injection-molded leaves. The robot arm is powered by electricity but operates pneumatically during operation. The entire machine operates according to a pre-programmed sequence.

Robot Arm Parameter

Body Width | 1480mm |

Body Height | 1500mm |

Allow the mold to be lower than the installation plane | 150mm |

Allow the mold to be higher than the installation plane | 150mm |

Maximum Wire Length | 350mm |

Wire Feeder Type | Distance adjustable, Type A |

| Wire Feeder Installation Method | Hanging |

| Number of Outlets | 1 or 2 |

| Wire diameter | 0.9mm-1.4mm |

| Line spacing | ≥28mm |

| Drainage method | Drainage method |

| Discharging method | Straight Line |

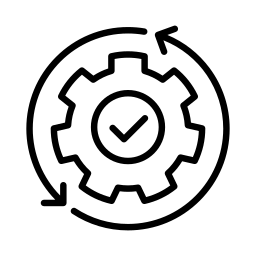

Advantages Of Robot Arm

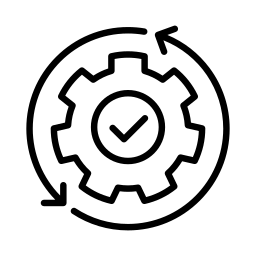

Automation

In the production of PE Christmas tree leaves, robotic arms are responsible for picking up materials, producing leaves, and placing finished products, thus automating the entire process.

High-Efficiency Production

From collecting the plastic-coated wire to placing the finished PE leaves on the product shelf, the robot arm completes the entire cycle in less than 10 seconds, greatly improving production efficiency.

Simplify production process

Robotic arms have replaced workers in the production of PE injection-molded leaves, completing most of the intermediate steps and realizing integrated PE leaf production.

Packaging And Shipping

Packaging

Generally, we use wooden crates to pack the machines. We place pallets at the bottom of the crates for easy transport, and reinforce the bottom inside the crates with wooden boards to secure the machine. We also include some easily damaged parts inside the crates to ensure long-term machine use.Of course, if you have special packaging requirements, we can also customize packaging for you.

Shipping

The machine supports both air and rail transport; you can choose the delivery method that best suits your needs. We will notify the factory to begin production upon order confirmation. After completion, the machine will be tested, and once confirmed to be working correctly, it will be packed and delivered to the designated location. If you have a local agent in your area, we can also deliver the machine to them, who will handle the remaining shipping procedures.

FAQ

What is this robot arm mainly used for?

This robot arm is designed for the automated production of PE artificial Christmas tree leaves. It is mainly used to pick finished plastic leaves from the injection molding machine and place them onto a collection shelf, reducing manual handling and improving production efficiency.

What materials and products can the robot arm handle?

The robot arm is suitable for handling small and lightweight PE injection-molded products, especially PE Christmas tree leaves. It is optimized for repetitive pick-and-place operations in high-frequency production environments.

Is the robot arm fully automatic?

Yes. The robot arm operates according to a pre-programmed sequence. Once parameters are set, it can automatically complete picking, transferring, and placing operations with minimal manual intervention.

What kind of maintenance does the robot arm require?

Routine maintenance mainly includes cleaning, checking pneumatic components, and ensuring proper lubrication of moving parts. With proper maintenance, the robot arm can operate stably for long periods.

Can this robot arm work with different injection molding machines?

Yes. The robot arm can be integrated with most standard PE injection molding machines. Installation height and working range can be adjusted according to the mold position and machine layout.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá