Polyethylene terephthalate, commonly known as PET, plays a pivotal role across a plethora of industries due to its diverse range of applications and is symbolized by the number "1." Yet, amid its ubiquity, PET often remains an enigmatic presence, deserving a closer look into its characteristics, extensive usage, and its environmental role.

Introduction to PET Plastic

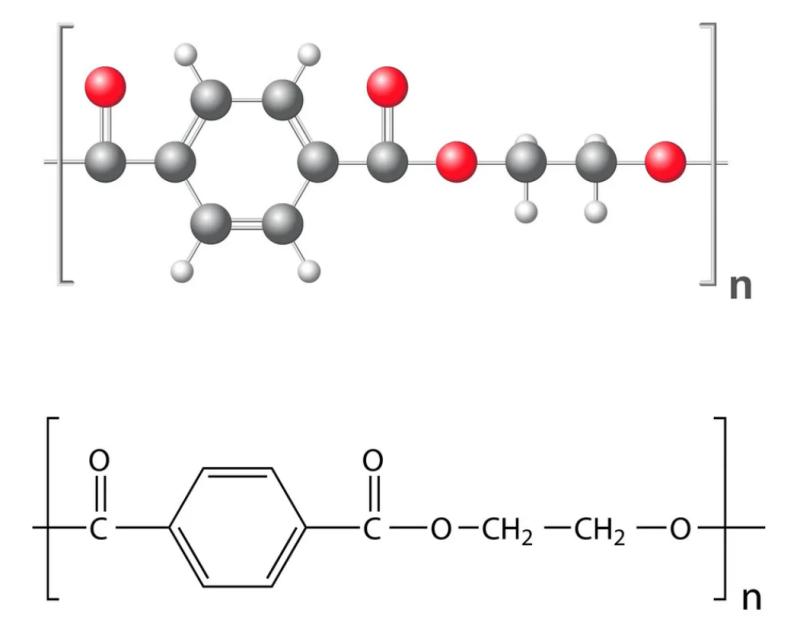

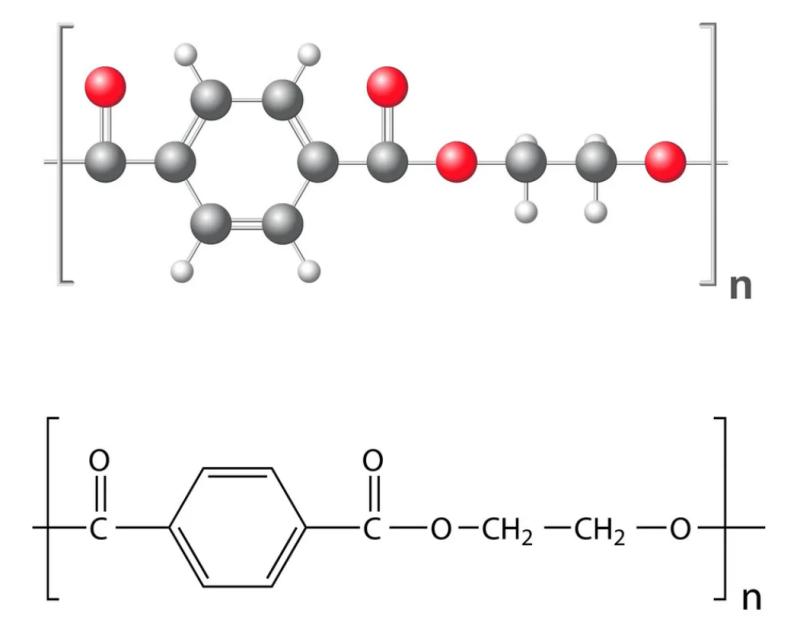

PET, or Polyethylene terephthalate, stands as a synthetic polymer that derives its significance from its chemical composition represented by the formula (C10H8O4)n. In the world of textiles, PET assumes the moniker "polyester," while in the realm of containers and packaging, it takes on the mantle of "PET resin."

Understanding PET Resin

What truly distinguishes PET is its exceptional array of physical attributes that endure across a wide spectrum of temperatures. Displaying remarkable mechanical properties, PET boasts a longevity of use even in the face of temperatures as high as 120°C. Its prowess in maintaining excellent electrical insulation properties, even under conditions of elevated temperature and frequency, renders it a choice material for a multitude of applications.

Versatile Applications of PET

Film and Packaging Materials:

One of PET's paramount roles lies in the realm of film and packaging. It gracefully serves as the bedrock for an assortment of food, pharmaceutical, and sterile packaging needs. Its qualities are further harnessed in the creation of premium packaging for delicate instruments, intricate electronics, and textiles that demand a touch of sophistication.

Bottle Packaging:

PET's journey through packaging has transcended its origins in carbonated beverages, evolving into a trusted companion for housing an array of contents. From beer to edible oils, condiments to pharmaceuticals and cosmetics, PET bottles hold a firm grip on the domain of container packaging.

Electronics and Electrical Components:

The versatility of PET isn't confined to consumables; it forays into the realm of electronics and electrical components. Its deployment extends to crafting connectors, intricate circuitry, capacitors, and a myriad of housings for electronic devices and appliances that permeate modern life.

Automotive Parts:

The automotive sector finds solace in PET as well. A broad spectrum of automotive components is molded and shaped by PET, including distribution panel covers, ignition coils, valves, exhaust elements, and meter instrument shells. The material's exceptional attributes, including exquisite coatings, surface luster, and rigidity, render it indispensable for crafting exterior automotive parts.

Machinery and Equipment:

From intricate machinery to everyday equipment, PET's influence is felt in the crafting of gears, cams, pump housings, pulleys, and motor frames. It even extends its reach into the creation of microwave oven trays, outdoor billboards, and intricate models that capture the imagination.

PET's Dominance in Packaging

As the cornerstone of beverage and rigid food packaging, PET's ubiquity is most pronounced in these sectors. It offers a level of translucency that showcases products with clarity, while its chemical stability ensures the preservation of content quality. The combination of mechanical robustness and resistance to impact further solidifies its role in safeguarding the integrity of packaged products.

Production Process of PET Plastic

The creation of PET involves a meticulous synthesis process where terephthalic acid and ethylene glycol engage in direct reactions. This process unfurls in two main stages: esterification, followed by condensation reactions. The resulting PET resin, once raised to a molten state, transforms into a malleable material, ready to be shaped into a multitude of forms.

Processing Guidelines for PET

Understanding PET's characteristics while in its molten state is pivotal to successful processing. Manipulating its viscosity through pressure alterations is a potent tool in shaping its flow behavior. The intriguing facet of PET's sensitivity to moisture necessitates a comprehensive drying process before processing, ensuring its structural and material integrity.

Identifying Genuine PET

Sensory Test:

PET's distinct fragrance, released when subjected to combustion, sets it apart from other plastics. This scent serves as a reliable marker of its authenticity, with a fragrance that is noticeably distinct from the acrid odor produced by other materials.

Visual Examination:

The combustion process of PET provides visual cues that reveal its unique qualities. Overwhelming blackening or rapid formation of oil droplets during combustion might signal irregularities in its melting points, a phenomenon more commonly observed in PET films.

Tensile Test:

An intriguing approach to differentiating PET involves subjecting a molten strand of the material to a tensile test. By observing the extent of curling in the strand and its behavior when broken, insights into its melting point and characteristics can be gleaned.

Safety of PET Plastic

PET's safety profile receives validation through certifications and approvals from renowned health and safety agencies. Institutions such as the US FDA, Health Canada, the European Food Safety Authority, and various others have scrutinized and approved PET's use in food and beverage containers. Its enduring safety record spanning decades serves as a testament to its reliability and consumer trust.

Recycling PET Containers

Within the realm of plastics, PET bottles emerge as a champion of recyclability. Their design inherently lends itself to efficient recycling practices, offering a potential for achieving 100% recycling rates. The packaging landscape has been revolutionized by PET's potential for circularity, serving as a cornerstone for sustainable packaging initiatives worldwide.

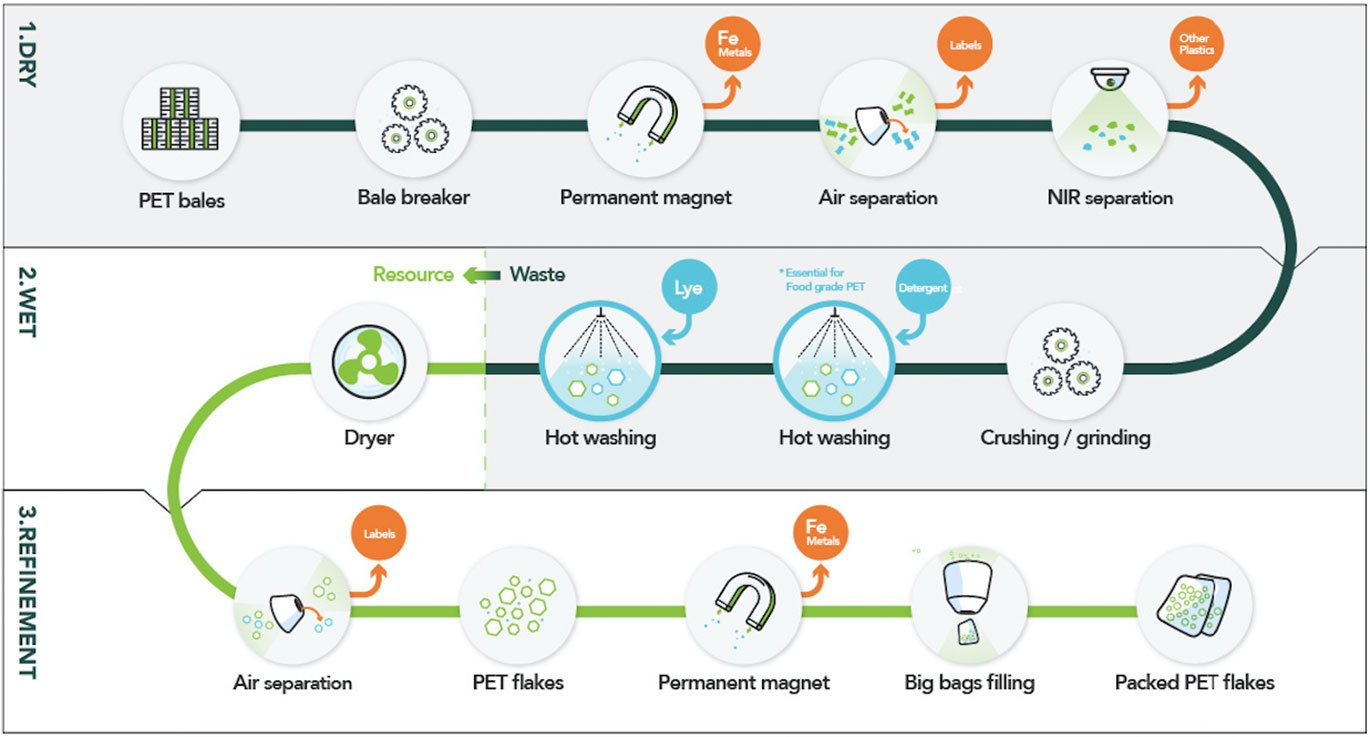

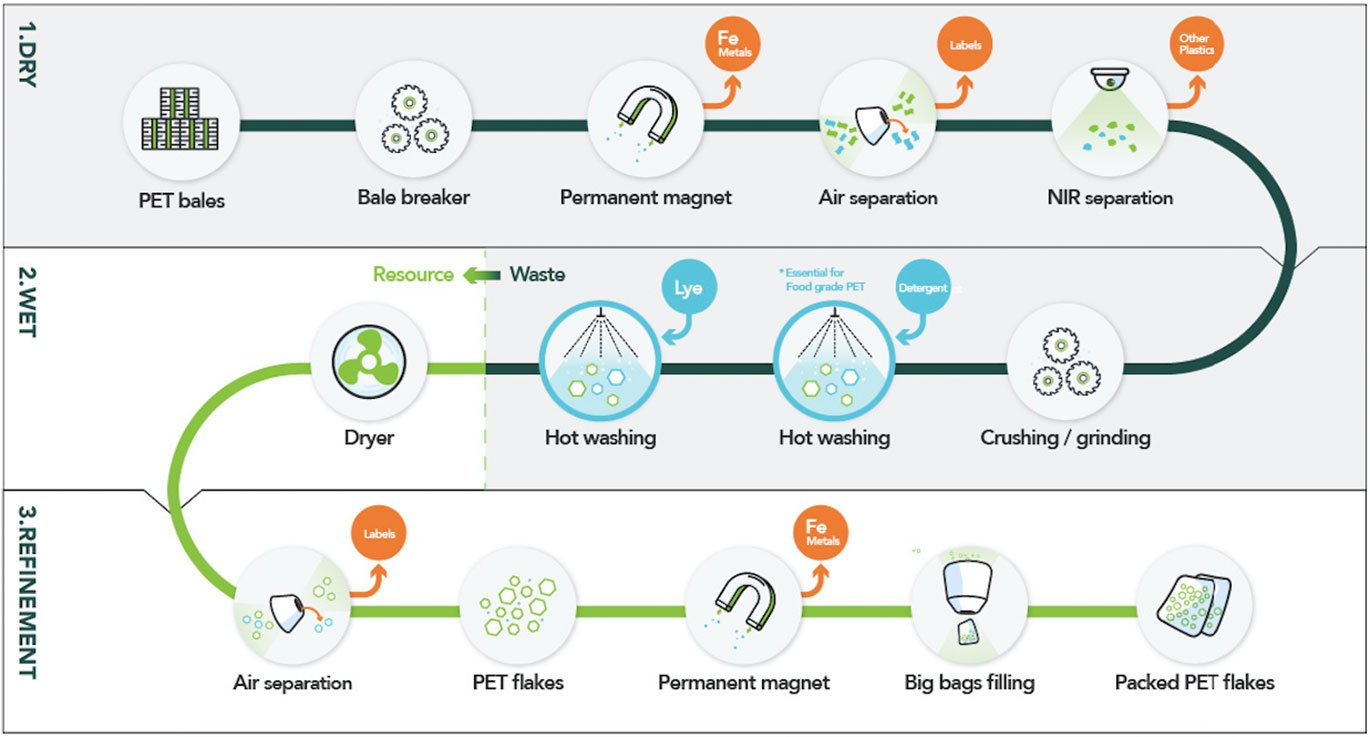

PET's Recycling Process

The recycling journey of PET bottles is characterized by several stages, each contributing to its transformation from discarded waste to valuable resources.

The recycling process unfolds as a choreographed sequence:

1. Label Removal (De-labeling):

PET bottles embark on their recycling journey by shedding their external identity. Specialized machinery carefully peels away labels and adhesives, leaving behind clean, ready-to-process PET containers.

2. Crushing and Shredding:

The transformed PET bottles move to the next stage, where they are subjected to crushing and shredding. This mechanical process reduces them to smaller fragments, facilitating subsequent handling and processing.

3. Sorting and Classification:

The now-shredded PET fragments are subjected to an intricate sorting process. Advanced technologies, such as optical scanners and air classifiers, identify and segregate PET from other materials based on their distinctive properties, such as color and polymer composition.

4. Cleaning and Washing:

Cleaning is a critical step that ensures the purity of the PET material. PET fragments are washed meticulously, removing any residual contaminants, labels, and adhesive residues. This thorough cleaning process restores the material's integrity and readies it for the next phases.

5. Drying:

Moisture content in recycled PET can negatively impact its quality and processing. Thus, the cleaned fragments undergo a drying process, ensuring that the moisture content is brought down to acceptable levels, thereby preserving the structural integrity of the material.

6. Pelletization:

The dried PET fragments are then transformed into uniform pellets through a pelletization process. These pellets serve as the raw material for various applications, ranging from textiles to packaging, electronics, and more.

Distinguishing PET and PETG

While PET and PETG both belong to the polyester family, they boast distinct characteristics that set them apart in specific applications.

PETG, a derivative of PET, shines when it comes to shaping complex forms and achieving high levels of elongation. One of its unique features is its ability to be processed without the need for pre-drying, in contrast to other materials like polycarbonate (PC) or impact-modified acrylics. Additionally, PETG's shorter molding cycles and lower processing temperatures contribute to higher yields during production, making it an attractive choice for manufacturers seeking efficiency without compromising on quality.

Conclusion

Polyethylene terephthalate, with its myriad applications and significance in modern society, is no longer a mysterious acquaintance. Its journey from synthesis to shaping, recycling, and even differentiation from its cousin PETG, showcases its remarkable versatility. As a cornerstone of packaging and an essential element in various industries, PET's attributes underscore its pivotal role in shaping our world sustainably. The journey of PET from a plastic material to a recyclable resource is a testament to human innovation and our commitment to reducing environmental impact. Through understanding and responsible utilization, PET continues to contribute to a more sustainable and functional future.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá