Product Overview: Traceable Excellence in Recycled Materials

The GRS certified RPET film from One Plastic is specifically engineered for brands that demand full transparency in their sustainable supply chain. The Global Recycled Standard (GRS) is more than just a label; it is a guarantee of verified recycled content, social and environmental responsibility, and rigorous chemical restrictions. Our RPET film allows you to meet global environmental mandates while maintaining the optical brilliance and mechanical strength required for premium industrial packaging.

Utilizing advanced purification technology, we transform post-consumer materials into high-quality rigid film rolls. This GRS-verified substrate is optimized for high-speed automated production, ensuring that your transition to sustainable packaging is both ethically sound and operationally efficient.

Technical Specifications: The GRS Quality Benchmark

| Item Name | RPET Film |

| Product | ROLL | SHEET |

| Thickness Range | 0.15-1.5mm | 0.15-2.0mm |

| Width Range | 0.15-0.4: 170-660mm

0.41-0.8:170-1250mm

0.81-1.50:500-1320mm | 0.15-0.25: 300-660mm

0.26-0.8:300-1250mm

0.81-2.0:500-1320mm |

| Length Range | / | 0.15-0.30:300-660mm

0.31-2.0:400-2440mm |

| Weight | 0.15-0.4: maximum 70KG/ROLL

0.41-0.8: maximum 100KG/ROLL

0.81-1.50: maximum 270KG/ROLL | normal:20-50KG/PACK |

| Specific Gravity | 1.35g/cm3 |

| Light Transmission | ≧85% |

| Tensile Strength | ≧44 |

| Vicat Softening Point | 60℃ |

| Surface | Usually glossy, can coated with protective film on one side or both side Usually transparent, can colored as customer's requirement. |

| Surface Pretreatment | Surface pretreatment is required before printing to improve the energy or wettability of the surface and to increase the adhesion of ink and ribbons. Surface treatment methods containing corona treatment, coating treatment,anti-stastic treatment,The surface on which PET film is applied must be free of dust, grease, lubricant and any other substances which may hinder the film from adhesion. |

| Suitable Ink | Eco-solvent , Solvent , Latex ,UV,water-based ink |

| Suitable Printing Method | UV offset printing, silk-screem printing, |

| Storage | The best temperature to store the product is about 30℃ in its original packaging, It's better to avoide damages from direct sunlight, high moisture and falling down; Best usded in three months. |

Key Performance Features

Fully Traceable GRS Certification:Every roll is backed by GRS certification, ensuring the recycled content is verified and tracked from the source. This transparency helps simplify your environmental auditing and enhances brand credibility with eco-conscious consumers.

Superior Clarity and Surface Finish:Despite its recycled origin, our RPET maintains impressive transparency and gloss. We minimize impurities to ensure a glass-like finish that acts as a premium window for your products.

Exceptional Structural Integrity:Specifically formulated for durability, our rigid GRS PET film provides high-impact resistance. It maintains its structural stability during deep-draw thermoforming, ensuring finished containers are sturdy and protective.

Reliable Barrier and Hygiene Standards:Non-toxic, odorless, and strictly compliant with FDA and SGS food-grade standards. Our material provides an effective shield against moisture and oils, preserving product quality across the global logistics chain.

Support for the Circular Economy:By choosing GRS certified materials, you are actively reducing the demand for virgin plastic and lowering carbon emissions, directly supporting your brand's ESG (Environmental, Social, and Governance) targets.

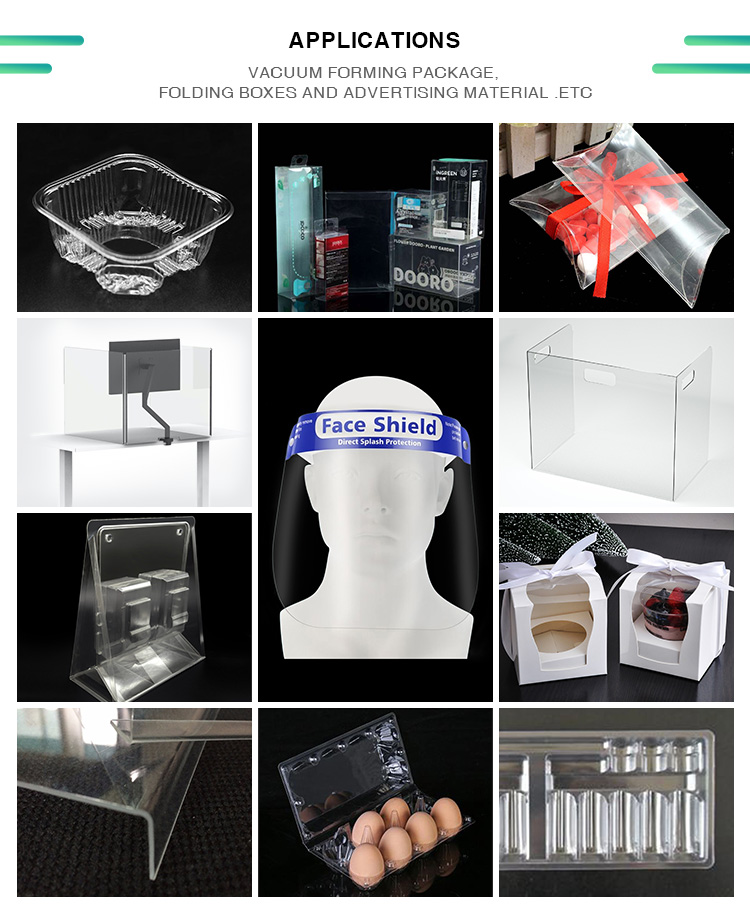

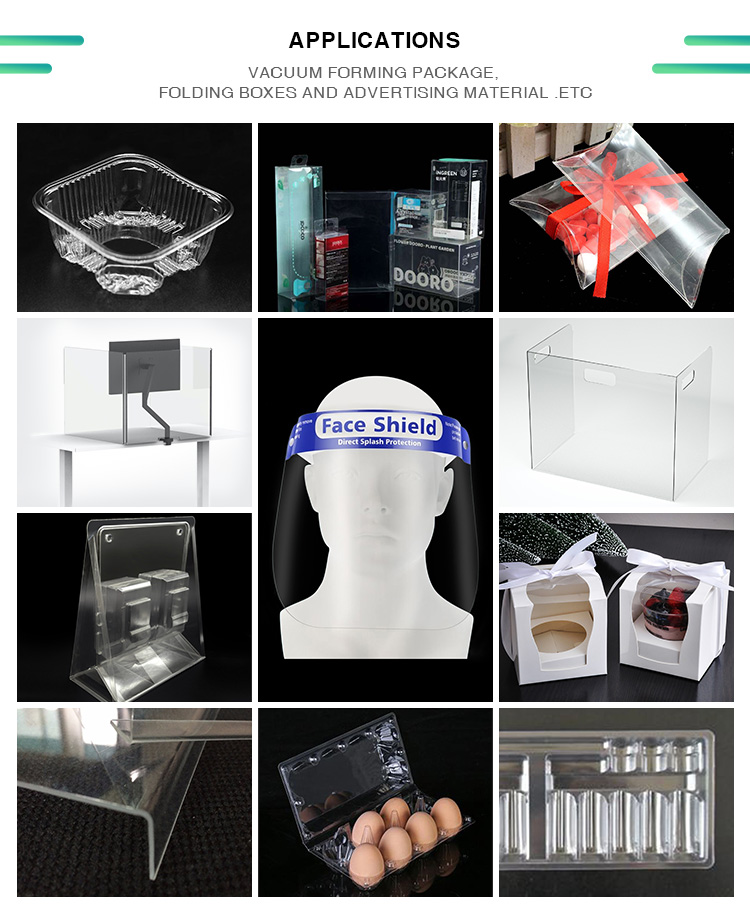

Targeted Industrial Applications

Certified Sustainable Food Packaging: Ideal for fruit trays and salad bowls where GRS verification is a key brand requirement.

Retail Blister Packaging: Providing rigid, transparent protection for electronics and cosmetics using verified recycled content.

Medical & Pharmaceutical Trays: Compliant with hygiene standards for sterile tool carriers and pharmaceutical blisters.

Luxury Folding Boxes: High-clarity, fold-resistant sheets for premium sustainable gift and retail packaging.

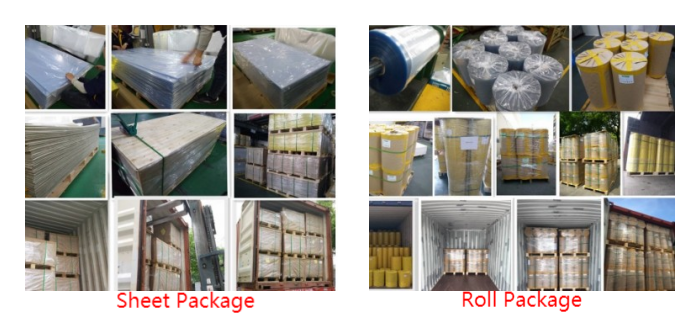

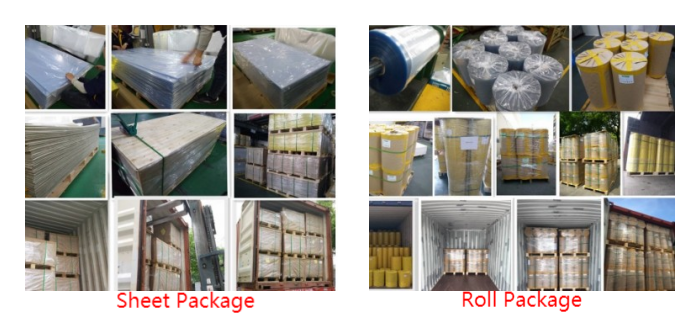

Packing and Transportation

GRS Certificated RPET Film packing details

Inner Packing: PE warp film

Out Packing: Kraft Paper+pallet and PE wrapping with protective corner.

Pallets packing: around 1000kg per wooden pallet

Container loading: 20-24 tons in a 20GP

Sea Port: SHANGHAI or NINGBO sea port

Leading time: 7 days for less than 5tons, 10-15 days for 20GP container

Payment term: 30% deposits; 70% balance against copy of original BL.

Why Source GRS RPET from One Plastic?

Verified Compliance: We provide a stable supply of GRS certified materials, simplifying your procurement process for global markets.

Precision Extrusion Capacity: Our automated lines ensure precise gauge control across every roll, reducing waste on your production machinery.

Global Export Expertise: We manage the entire export process, ensuring container orders are ready for shipment within 7-14 days with professional protective packaging.

FAQ: GRS Certification & Logistics

Q: What does the GRS certification guarantee for your RPET film?

Q: Does GRS certified RPET film look different from virgin PET?

Q: What is the typical lead time for a GRS certified wholesale order?

Q: Can I request customized samples for testing on my machinery?

Q: Is your GRS certified material safe for food-contact packaging?

A: Absolutely. All our GRS certified RPET films are manufactured to comply with FDA and SGS standards, ensuring they are non-toxic, odorless, and safe for global food and pharmaceutical packaging.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá