High-Performance PET Sheet: The Ideal Material for Thermoforming

PET plastic sheet (specifically APET) is widely recognized as the industry standard for high-quality thermoforming and vacuum forming applications. Our materials are engineered to provide a wide processing window, ensuring consistent performance on high-speed automated production lines.

By balancing exceptional optical clarity with superior mechanical strength, our PET sheets allow manufacturers to create durable, high-visibility packaging—ranging from intricate retail blisters to deep-draw food trays. Our commitment to using high-purity resins ensures that every roll offers the dimensional stability and barrier protection required for modern industrial packaging solutions.

Technical Specifications & Material Parameters

| Item Name | PET Plastic Sheet for Thermoforming | PET Plastic Sheet for Thermoforming |

| Product Type | ROLL | SHEET |

| Thickness Range (mm) | 0.15-1.5 | 0.15-2.0 |

| Width Range (mm) | 0.15-0.4: 170-660, 0.41-0.8:170-1250, 0.81-1.50:500-1320 | 0.15-0.25: 300-660, 0.26-0.8:300-1250, 0.81-2.0:500-1320 |

| Length Range (mm) | N/A | 0.15-0.30:300-660, 0.31-2.0:400-2440 |

| Weight (KG) | 0.15-0.4: max 70/ROLL, 0.41-0.8: max 100/ROLL, 0.81-1.50: max 270/ROLL | Typical: 20-50/PACK |

| Specific Gravity (g/cm3) | 1.35 |

|

| Light Transmission | ≧85% |

|

| Tensile Strength | ≧44 |

|

| Vicat Softening Point (℃) | 60 |

|

| Surface Characteristics | Glossy (typical), protective film options, typically transparent but customizable colors |

|

| Surface Pretreatment Details | Essential pre-printing surface treatment includes methods like corona, coating, and anti-static treatments. Ensure a dust and grease-free surface for optimal adhesion. |

|

| Appropriate Ink Types | Eco-solvent, Solvent, Latex, UV, water-based |

|

| Recommended Printing Methods | UV offset printing, silk-screen printing |

|

| Storage Recommendations | Optimal storage at 30℃ in original packaging, protected from sunlight, moisture, and physical damage. Best used within three months. |

|

Advanced Product Features

1. Unmatched Safety & Material Purity

2. High Clarity & Surface Gloss

3. Superior Impact Strength & Toughness

4. Industrial-Grade Barrier Performance

5. Sustainable Packaging Solutions

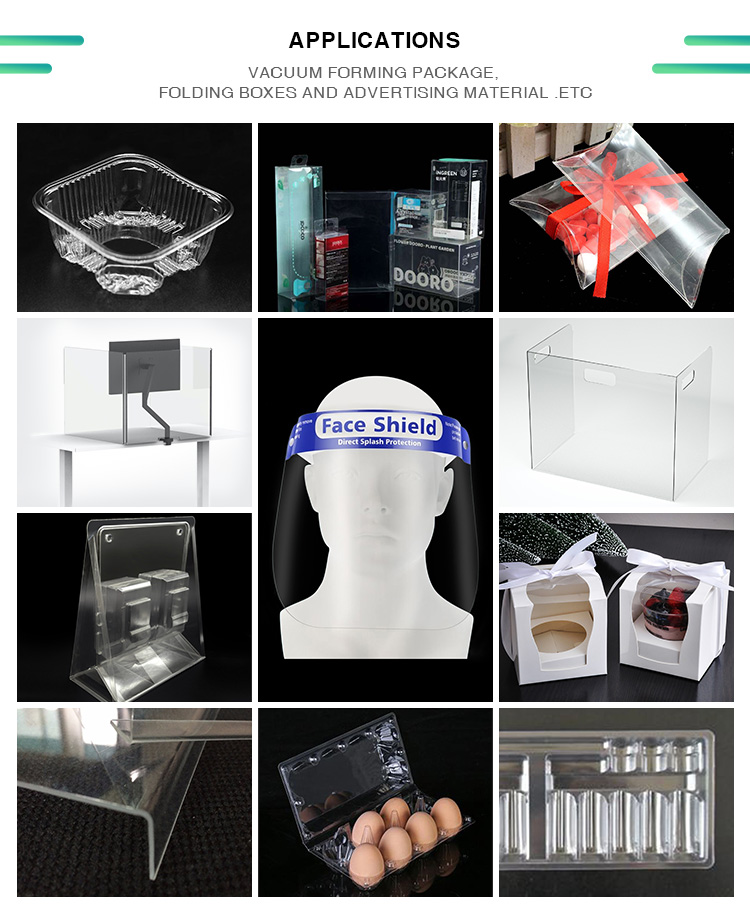

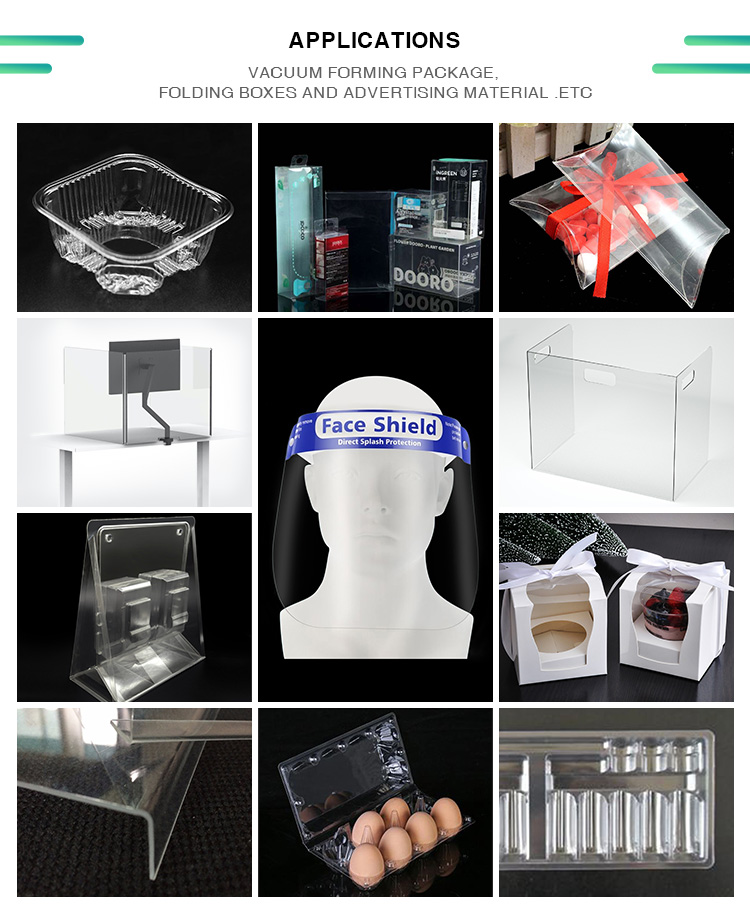

Specialized Applications in Thermoforming Industry

Vacuum Forming for Food Containers

Ideal for fruit punnets, salad bowls, and egg trays.For refrigerated items, we recommend our [Anti-Fog PET Film](https://one-plastic.com/Anti-Fog-PET-Film-pd44721409.html) to maintain clear visibility under varying temperatures.

Blister Packaging for Electronics & Hardware

Provides high rigidity and clarity for clamshells, protecting sensitive components while showcasing product details.

Medical & Pharmaceutical Trays

Produced under strict hygiene controls to meet the requirements of sterile medical tool packaging and pill blisters.

Why Source from ONE Plastic?

State-of-the-Art Automated Production

We utilize advanced multi-layer extrusion lines that guarantee thickness uniformity—a critical factor for avoiding "thin spots" during thermoforming.

Comprehensive Quality Control System

Each batch undergoes a rigorous inspection protocol, testing for thermal stability, impact resistance, and surface purity.

Expert Technical Support

Our engineers understand the complexities of vacuum forming and can provide customized material solutions to match your specific machinery and cycle times.

Frequently Asked Questions (FAQ)

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá