Product Overview: Balancing Efficiency and Performance

The PET rigid sheet roll is the preferred material for manufacturers seeking a high-performance, cost-effective solution for large-scale packaging. Our rigid rolls are engineered to deliver a unique combination of optical clarity and mechanical toughness. Specifically optimized for high-speed automated production lines, these rolls provide the dimensional stability required for precision vacuum forming and complex blister packaging.

At One Plastic, we utilize advanced multi-layer co-extrusion technology to ensure that every roll meets the highest industrial standards. By focusing on consistent thickness and superior surface tension, we help our global partners minimize material waste and maximize their production throughput.

Technical Specifications: Data-Driven Quality

| Item Name | Wholesale PET Rigid Sheet Rolls |

|

| Product | ROLL | SHEET |

| Thickness Range | 0.15-1.5mm | 0.15-2.0mm |

| Width Range | 0.15-0.4: 170-660mm0.41-0.8:170-1250mm0.81-1.50:500-1320mm | 0.15-0.25: 300-660mm0.26-0.8:300-1250mm0.81-2.0:500-1320mm |

| Length Range | / | 0.15-0.30:300-660mm0.31-2.0:400-2440mm |

| Weight | 0.15-0.4: maximum 70KG/ROLL0.41-0.8: maximum 100KG/ROLL0.81-1.50: maximum 270KG/ROLL | normal:20-50KG/PACK |

| Specific Gravity | 1.35g/cm3 |

|

| Light Transmission | ≧85% |

|

| Tensile Strength | ≧44 |

|

| Vicat Softening Point | 60℃ |

|

| Surface | Usually glossy, can coated with protective film on one side or both sides Usually transparent, can colored as per the customer's requirement. |

|

| Surface Pretreatment | Surface pretreatment is required before printing to improve the energy or wettability of the surface and to increase the adhesion of ink and ribbons. Surface treatment methods include corona treatment, coating treatment, and anti-static treatment, The surface on which PET film is applied must be free of dust, grease, lubricant, and any other substances which may hinder the film from adhesion. |

|

| Suitable Ink | Eco-solvent, Solvent, Latex, UV, water-based ink |

|

| Suitable Printing Method | UV offset printing, silk-screen printing, |

|

| Storage | The best temperature to store the product is about 30℃ in its original packaging, It's better to avoid damages from direct sunlight, high moisture, and falling down; Best used in three months. |

|

Core Performance Features: Why Our PET Rigid Rolls Lead the Industry

Optimum Clarity & Surface Finish: Our rolls are produced in a controlled environment to ensure zero-distortion visibility and a high-gloss finish, essential for premium retail displays.

Superior Thermoforming Performance: Designed with a wide processing window, our material offers consistent heating and cooling characteristics, ensuring a high yield in automated vacuum forming.

Structural Integrity & Barrier Protection: The molecular structure provides a reliable barrier against moisture and oxygen, while the high tensile strength protects contents from external pressure.

Chemical Safety & Purity: Non-toxic and odorless formulation. We ensure our PET is free from harmful additives, making it fully compliant with international food safety codes.

Eco-Friendly Lifecycle: Highly recyclable and supporting circular economy goals. Our PET material helps brands achieve their sustainability targets without sacrificing performance.

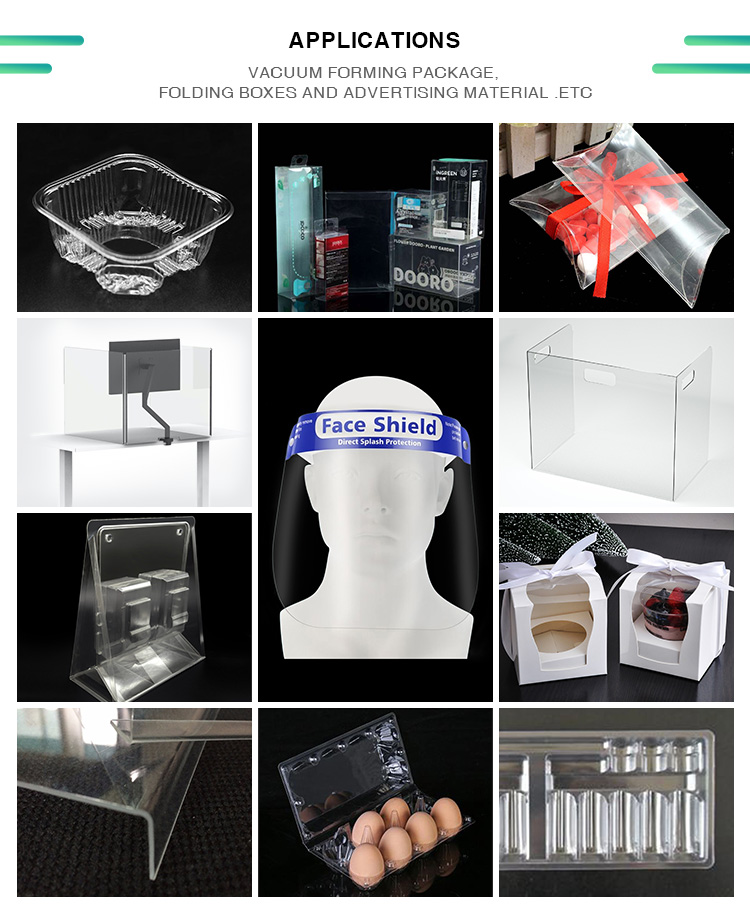

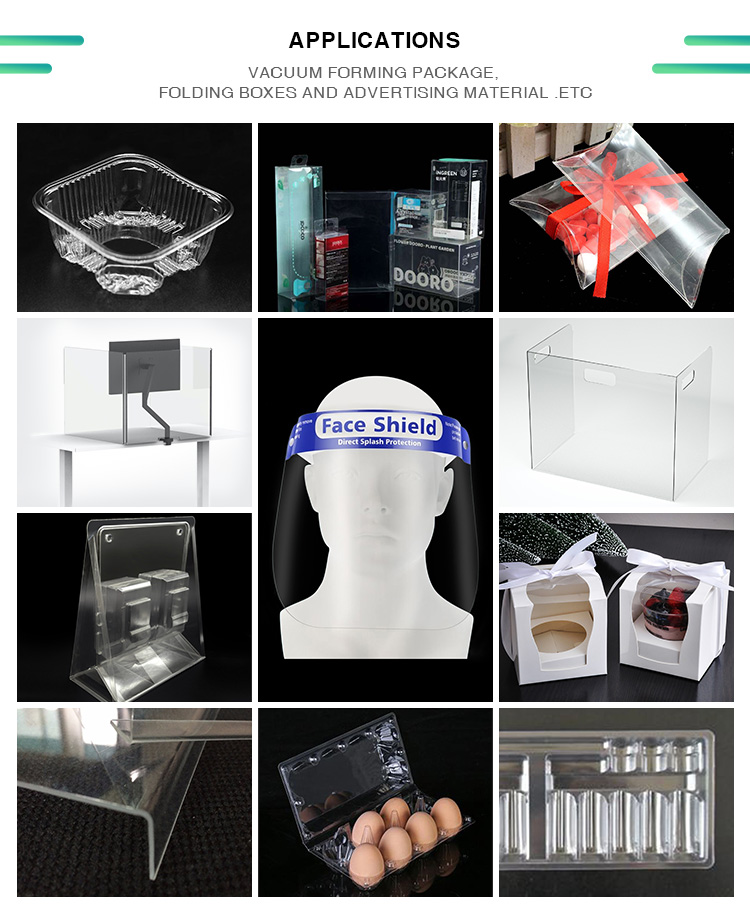

Versatile Applications: From Retail to Industrial Protection

Custom Retail Packaging: Perfect for clamshells and blisters for electronics, toys, and cosmetics, where aesthetics and protection are equally important.

Food-Grade Solutions: Ideal for manufacturing rigid trays for fresh fruit, vegetables, and confectionery, maintaining freshness with high barrier properties.

Medical & Sterile Trays: Provides a safe, clean environment for surgical tool packaging and pharmaceutical blisters.

Folding Box Grade: The rigidity and fold-resistance of our material make it a top choice for high-end transparent gift and retail boxes.

Industrial Component Carriers: Durable and impact-resistant, suitable for heavy hardware or sensitive automotive part carriers.

Why Source from ONE Plastic Factory?

Scalable Production Capacity: Our state-of-the-art extrusion lines allow us to support high-volume wholesale orders with stable lead times.

Precision Quality Control: Every roll undergoes a rigorous inspection for thickness uniformity, clarity, and winding tension.

Technical Partnership: We don't just supply material; our engineers provide technical guidance to help optimize your machinery settings for our PET rolls.

FAQ: Wholesale Pricing & Customization

Q: How does your wholesale pricing compare to market rates?

Q: Can we request custom surface treatments?

Q: What is your standard lead time for container orders?

Q: How do you handle export packaging to prevent damage?

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá