Product Overview: Eliminating Condensation for Maximum Visibility

The Anti-Fog PET plastic sheet is a specialized high-clarity material engineered to prevent the formation of water mist on the surface of packaging. In refrigerated or humid environments, standard plastic often becomes cloudy due to condensation. Our anti-fog sheets utilize advanced surface treatment technology to maintain a crystal-clear appearance, ensuring that the consumer’s first look at the product is always fresh and appealing.

Designed primarily for the food sector, One Plastic’s anti-fog material balances mechanical rigidity with long-lasting fog resistance. By optimizing the surface tension of the sheet, we ensure that moisture spreads into a thin, invisible film rather than forming obstructive droplets, making it the industry standard for premium cold-chain packaging solutions.

Technical Specifications: Anti-Fog Performance Data

| Item Name | Anti-Fog PET Plastic Sheet |

| Product | ROLL | SHEET |

| Thickness Range | 0.15-1.5mm | 0.15-2.0mm |

| Width Range | 0.15-0.4: 170-660mm

0.41-0.8:170-1250mm

0.81-1.50:500-1320mm | 0.15-0.25: 300-660mm

0.26-0.8:300-1250mm

0.81-2.0:500-1320mm |

| Length Range | / | 0.15-0.30:300-660mm

0.31-2.0:400-2440mm |

| Weight | 0.15-0.4: maximum 70KG/ROLL

0.41-0.8: maximum 100KG/ROLL

0.81-1.50: maximum 270KG/ROLL | normal:20-50KG/PACK |

| Specific Gravity | 1.35g/cm3 |

| Light Transmission | ≧85% |

| Tensile Strength | ≧44 |

| Vicat Softening Point | 60℃ |

| Surface | Usually glossy, can coated with protective film on one side or both side Usually transparent, can colored as customer's requirement. |

| Surface Pretreatment | Surface pretreatment is required before printing to improve the energy or wettability of the surface and to increase the adhesion of ink and ribbons. Surface treatment methods containing corona treatment, coating treatment,anti-stastic treatment,The surface on which PET film is applied must be free of dust, grease, lubricant and any other substances which may hinder the film from adhesion. |

| Suitable Ink | Eco-solvent , Solvent , Latex ,UV,water-based ink |

| Suitable Printing Method | UV offset printing, silk-screem printing, |

| Storage | The best temperature to store the product is about 30℃ in its original packaging, It's better to avoide damages from direct sunlight, high moisture and falling down; Best usded in three months. |

Core Product Features: Why Choose Anti-Fog PET?

Exceptional Anti-Fog Performance:Our sheets are engineered to provide consistent fog resistance in temperature transitions. Whether moving from room temperature to cold storage or back, the surface remains clear, preventing the "cloudy" effect that can deter customers.

Superior Transparency and Optical Gloss:Beyond fog resistance, our PET material offers high optical gloss. This ensures that the natural colors of fruits, vegetables, and meats are showcased vividly, significantly enhancing retail shelf appeal.

High Hygiene and Material Safety:Safety is our priority. The anti-fog agents used are non-toxic, odorless, and strictly meet FDA and SGS requirements. The material ensures no chemical migration, preserving the flavor and safety of the food.

Excellent Strength and Toughness:Even with specialized coatings, our sheets maintain high mechanical strength. They are ideal for vacuum forming complex shapes, ensuring that trays and lids remain sturdy and protective throughout the logistics chain.

Reliable Barrier and Shelf Life Protection:Provides a robust barrier against moisture and odors. By maintaining a stable internal environment, our PET sheets help extend the freshness and shelf life of perishable goods.

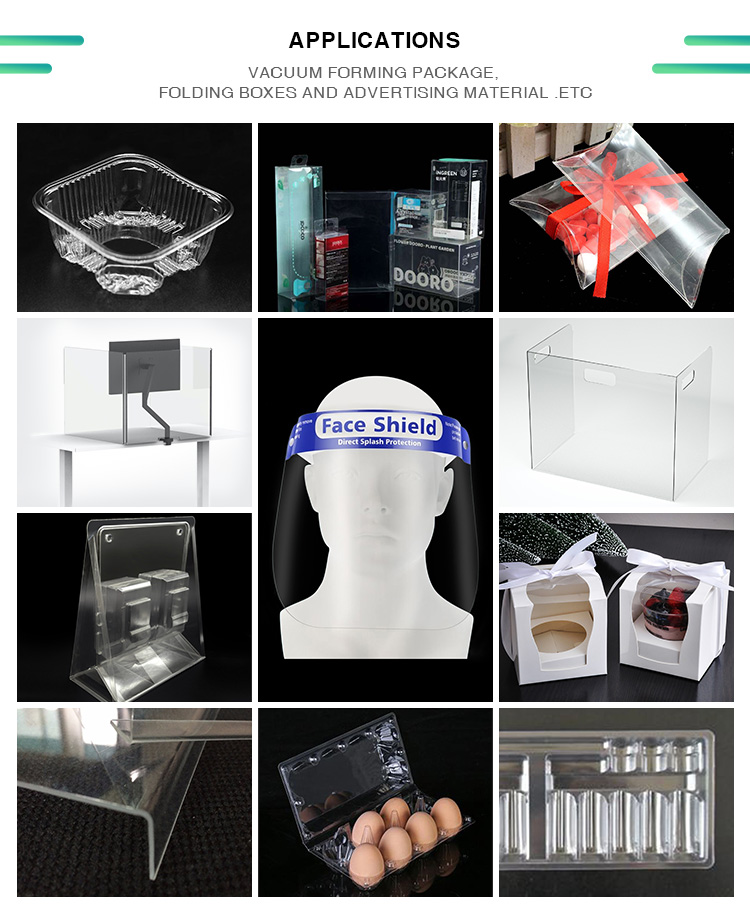

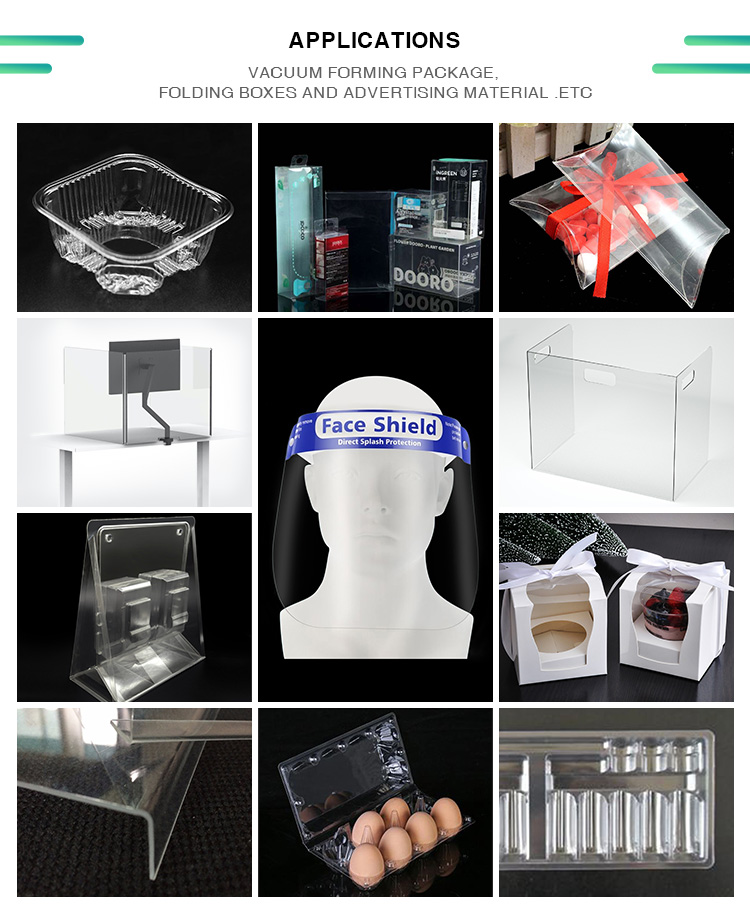

Product Application

Anti-Fog Protective Shields: Utilized in safety visors and medical face shields where zero-distortion, fog-free vision is critical for professional use.

Fresh Produce & Fruit Trays: The most common application for berries, grapes, and salad mixes where clear visibility is essential for the consumer.

Meat and Poultry Packaging: Prevents moisture from the meat from clouding the lid, ensuring the product looks appetizing and safe.

Refrigerated Deli & Ready-Meal Lids: Perfect for pre-packaged meals that go from the cold shelf to the consumer’s home.

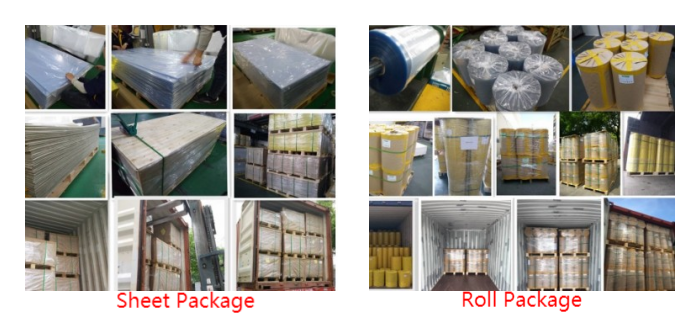

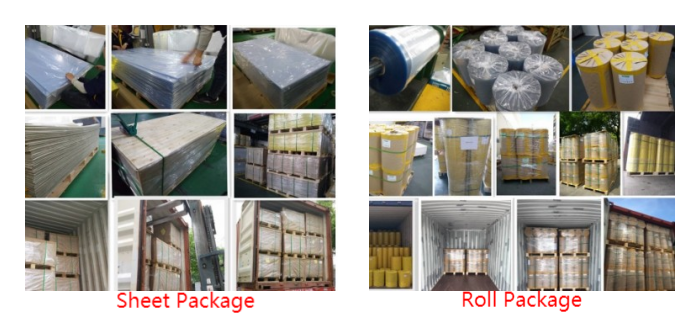

Packing and Transportation

Anti Fog PET Plastic Sheet packing and transportation

PET film packing details

Inner Packing: PE warp film

Out Packing: Kraft Paper+pallet and PE wrapping with protective corner.

Pallets packing: around 1000kg per wooden pallet

Container loading: 20-24 tons in a 20GP

Sea Port: SHANGHAI or NINGBO sea port

Leading time: 7 days for less than 5tons, 10-15 days for 20GP container

Payment term: 30% deposits; 70% balance against copy of original BL.

Why Source from One Plastic Factory

Advanced Coating Technology: We utilize state-of-the-art automated production lines to ensure that the anti-fog treatment is applied uniformly across the entire roll, preventing "dead spots" or uneven performance.

Consistent Quality Control: Each batch of anti-fog PET is tested in simulated cold-storage environments to verify its performance before it leaves our factory.

Customized Solutions: We offer tailored thickness, width, and even double-sided anti-fog treatments to solve your most challenging packaging requirements.

FAQ: Sourcing Anti-Fog PET Sheets Wholesale

1. What is Polyester Film used for?

The transparency of Polyester Film is high, and it’s more glossy compare to other plastics. More importantly the cost of PET film is lower than PVC film, so PET film is slowly replacing the use of PVC in many areas. Now PET film are widely used in packaging industry, such as food packaging, electronic products packaging, cosmetic packaging, and medical packaging etc.

2. What is the raw material of Polyester Film?

Polyester Film are made by Pet Chips(polyethylene terephthalate granules)

3. What is the normal size of Polyester Film?

There are different sizes Polyester Film, the regular size is 700*1000MM. We accept customized size PET sheet, the MOQ is 500kgs.

4. Can I get free sample for Polyester Film?

Yes, we can provide A4 size Polyester Film sample for free, you just need to pay for the delivery cost.

5. Can you recommend a China Polyester Film supplier?

ONE PLSTIC, one of the leading Polyester Film supplier and manufacturer in China, established in 2012. We have two factories, they are providing PET sheets&Film, PETG film, APET film, RPET film, GAG film, BOPET film and other plastic packing material

6. What is the production leading time for Polyester Film?

There are 10 Polyester Film extrusion lines in our factory, the production leading time is 5-7 days for 10 tons order quantity,10-15 days for full container quantity.

7. What I can buy Polyester Film?

One plastic is a leading Polyester Film manufacturer in China, you can send us enquiry and get the latest quotation.

8. Is polyester Film transparent?

There are many different types of Polyester Film, such as transparent PET film, opaque PET film, we also accept customized col PET film, MOQ is 1000KGS per col.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá