Product Introduction

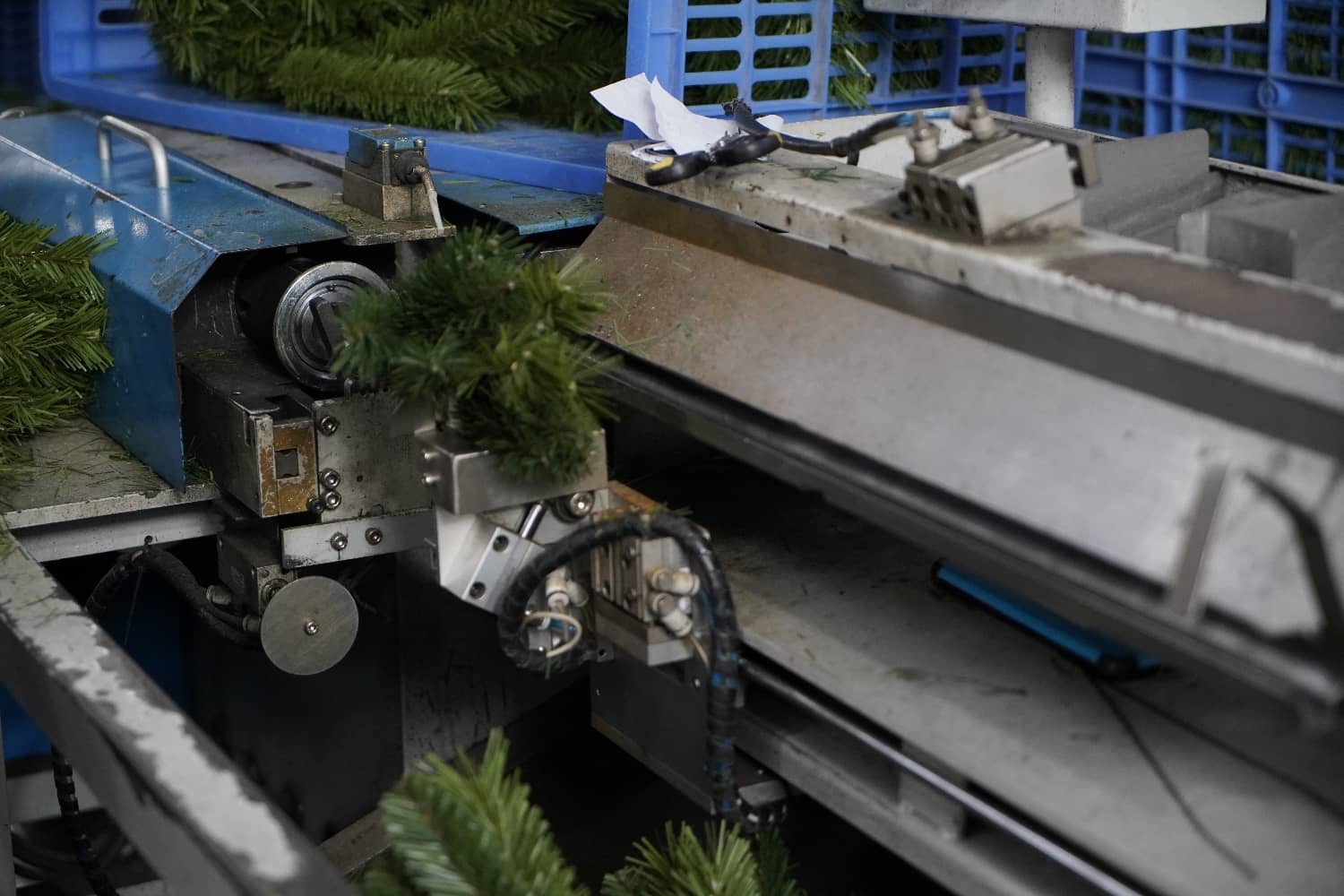

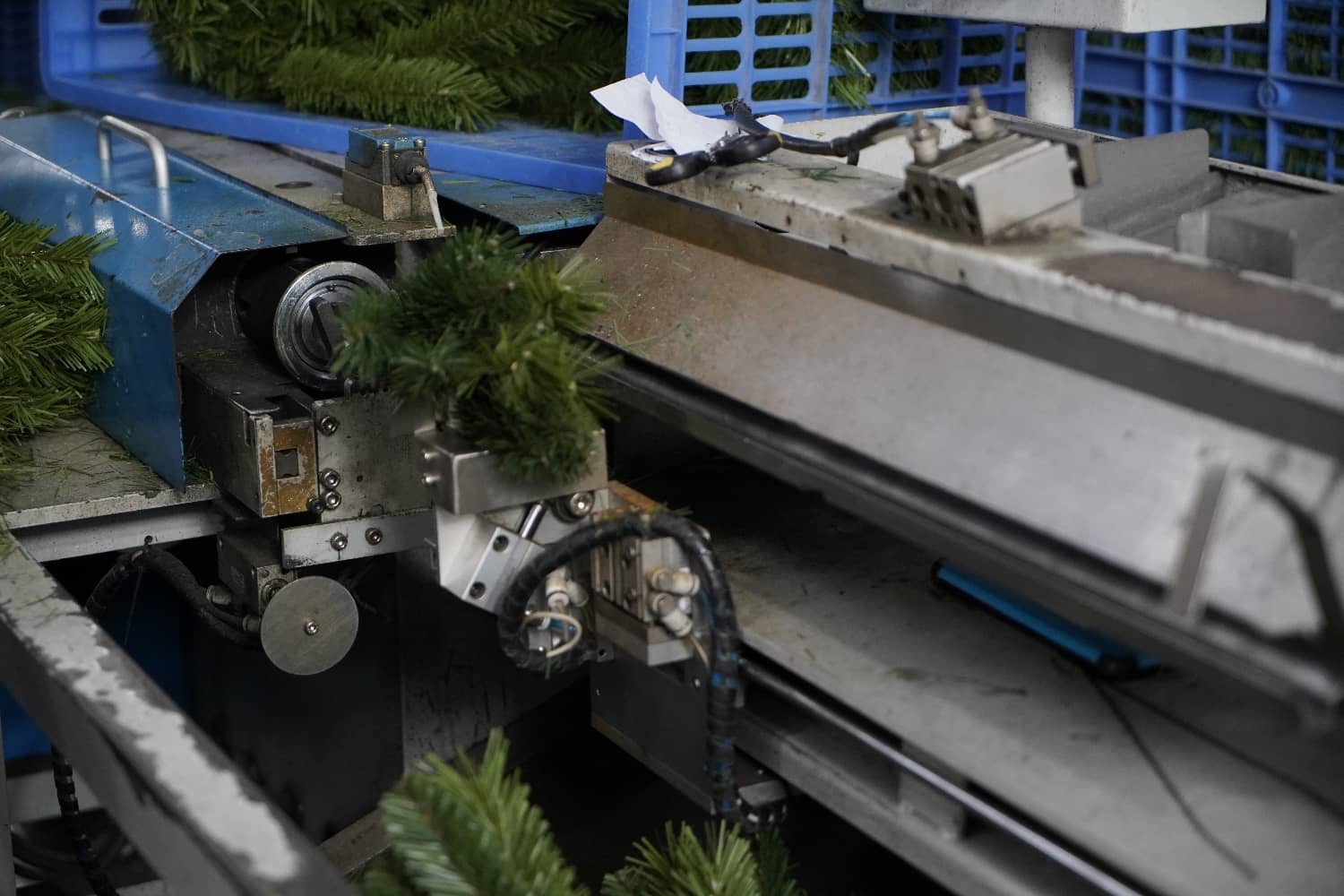

The artificial Christmas tree branch tying machine is a crucial part of artificial Christmas tree production. The machine is controlled via a control panel, allowing for fine adjustments to the tying process by changing parameters such as the spacing between branches and the speed at which the wire is tied.

Streamlining Branch Assembly with Precision Binding

By utilizing automated iron wire binding technology, this machine significantly simplifies the branch assembly process. It reduces reliance on skilled labor while ensuring that every branch remains tight and uniform even under high-speed operation, laying a high-quality foundation for final tree assembly.

Artificial Christmas Tree Branch Binding Machine Parameter

| Device Name | Branch Binding Machine |

| Overall Dimension | 1940mm*620mm*1060mm |

| Package Size | 1760mm*640mm*940mm |

| Rated Voltage | 220V |

| Rated Power | 1200W-1700W |

| Applicable Wire | 2-6 mm Straight/Bent Hook Wire |

| Product Suitable For | Christmas tree branch binding production. The iron wire is 100-650mm long and 2-6 mm in diameter in 1-20 segments with 1 to 8 pine leaves in each. |

| Designed Speed | 20000-40000 Leaves/Day |

| Number Of Binding Segments | Segment 1-20 |

| Thread Finish | Ultrasonic Wave |

| Automatic wire sorting, diameter 2-6 mm. |

| Automatic segmental binding, segment 1-20. |

| Automatic end-knotting, no smoke, no smell, no heating. |

| Computer intelligent control, accurate, energy saving. |

| Touch the screen for man-machine dialogue in Chinese,set parameters and monitor the equipment running status. |

| One key start and stop, automatic fault detection, automatic alarm and stop. |

Motor Power and Mechanical Capacity

Motor Power: [1.2kW-1.7kW]

Production Speed: [20000-40000pcs/day]

Operation Mode:Full-automatic

Wire Compatibility and Material Specifications

Wire Diameter: [2.0mm - 6.0mm]

Applicable Materials: PVC, PE, PET

Advantages Of Branch Binding Machine

Highly Efficient

Compared to manual branch tying machines, this machine can automatically complete the tying and wire removal processes, saving operators a significant amount of time.

Multilingual

Branch-binding machines enable localized deployment in multiple languages. We can modify the machine's voice to suit your specific language requirements.

Automation

The branch binding machine automates several aspects, such as leaf binding, automatic retraction and locking, and coil fuse breaking, thus significantly reducing the overall workload.

Proven Reliability for 24/7 Continuous Operation

Built with an industrial-grade thickened frame and wear-resistant transmission parts, this machine has undergone thousands of stress tests. It is capable of supporting 24/7 continuous operation during peak production seasons, providing a reliable guarantee for large-scale order fulfillment.

Low Maintenance Cost & Simple Operation

The ergonomic design allows new employees to start operating with minimal training. Key components use standardized parts, making daily maintenance simple and reducing the cost of replacement parts—an ideal choice for new factories seeking cost-effective production.

Application Of Branch Binding Machine

In the production of artificial Christmas trees, branch binding machines are mainly used to produce small branches for artificial Christmas trees. They bind cut PVC leaves or injection-molded PE into branches of a specific size, and then the head branch binding machine completes the binding of the trunk.

Ideal for Mixed Needle, PVC, and PE Branches

Whether your product uses classic PVC film, highly realistic PE tips, or slender pine needle materials, this machine is perfectly compatible. The multi-functional fixture design ensures that different materials stay securely in place during the binding process.

Customizable Settings for Various Branch Lengths

The workbench and sensing system can be quickly adjusted according to the length of the branches, flexibly handling orders for everything from small tabletop trees to large-scale landscape trees.

Packaging And Shipping

Secure Export-Standard Packaging

Generally, we use wooden crates to pack the machines. We place pallets at the bottom of the crates for easy transport, and reinforce the bottom inside the crates with wooden boards to secure the machine. We also include some easily damaged parts inside the crates to ensure long-term machine use.Of course, if you have special packaging requirements, we can also customize packaging for you.

Global Shipping & Logistics Solutions

The machine supports both air and rail transport; you can choose the delivery method that best suits your needs. We will notify the factory to begin production upon order confirmation. After completion, the machine will be tested, and once confirmed to be working correctly, it will be packed and delivered to the designated location. If you have a local agent in your area, we can also deliver the machine to them, who will handle the remaining shipping procedures.

We also provide 24/7 after-sales service. Please feel free to contact us at any time with any logistics or installation issues.

FAQ

Is this branch binding machine suitable for both PVC and PE Christmas trees?

Yes. This machine is suitable for both PVC and PE artificial Christmas tree production lines and can be used in different tree structures and branch specifications.

What types of wire can this branch binding machine use?

The machine supports straight or bent hook iron wire with a diameter of 2–6 mm, making it suitable for most standard artificial Christmas tree branch structures.

How many binding segments can the machine handle?

The branch binding machine supports 1–20 binding segments, allowing flexible adjustment based on branch length and tree design requirements.

What is the production capacity of the branch binding machine?

The designed output is approximately 20,000–40,000 leaves per day, depending on branch structure, wire length, and production settings.

Can the machine parameters be adjusted?

Yes. Operators can adjust binding speed, segment spacing, and binding length through the control system to match different artificial Christmas tree branch specifications.

Does this machine include an automatic hook-bending function?

Answer: This model is our Standard High-Speed Branch Binder, focusing on the binding process. If you require a "one-step" operation for both binding and hook-bending, please check our Hook-Forming and Branch-Binding In-One Machine.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá