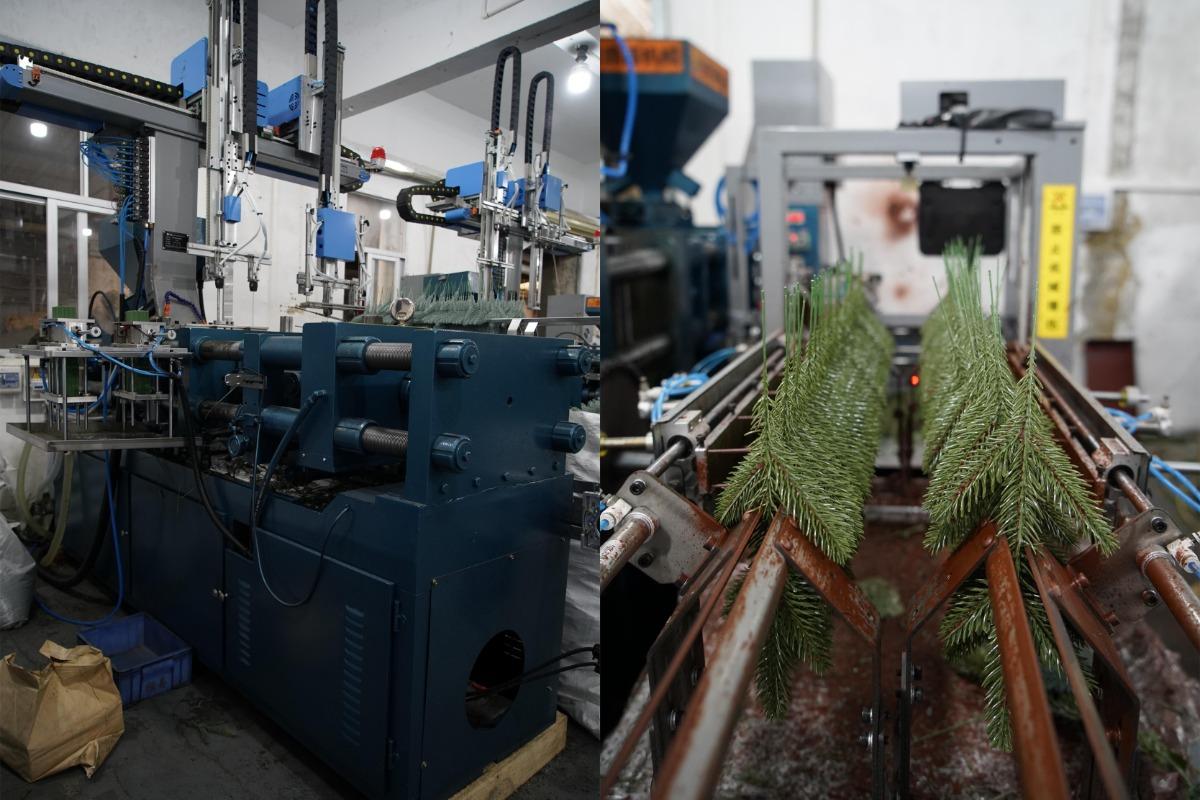

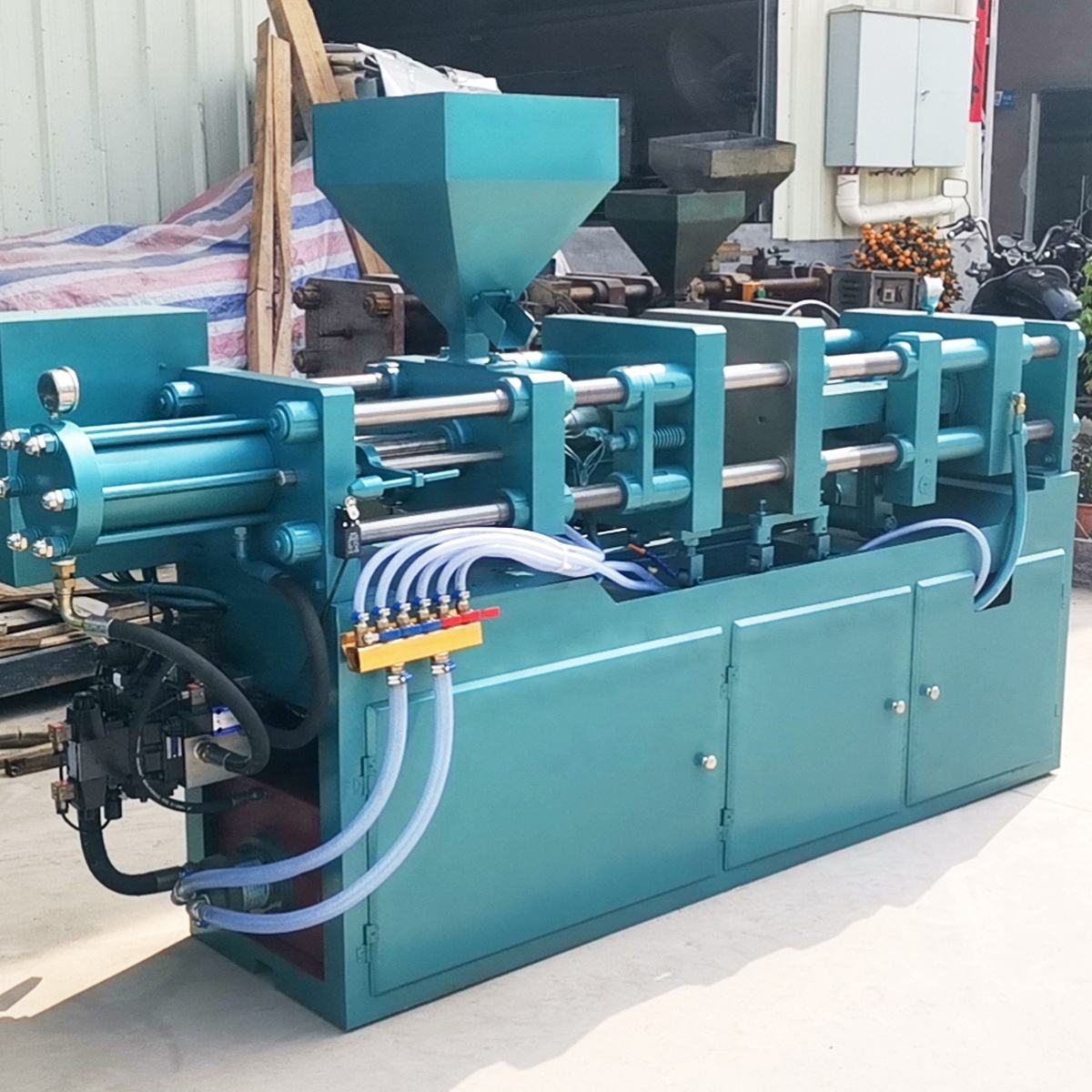

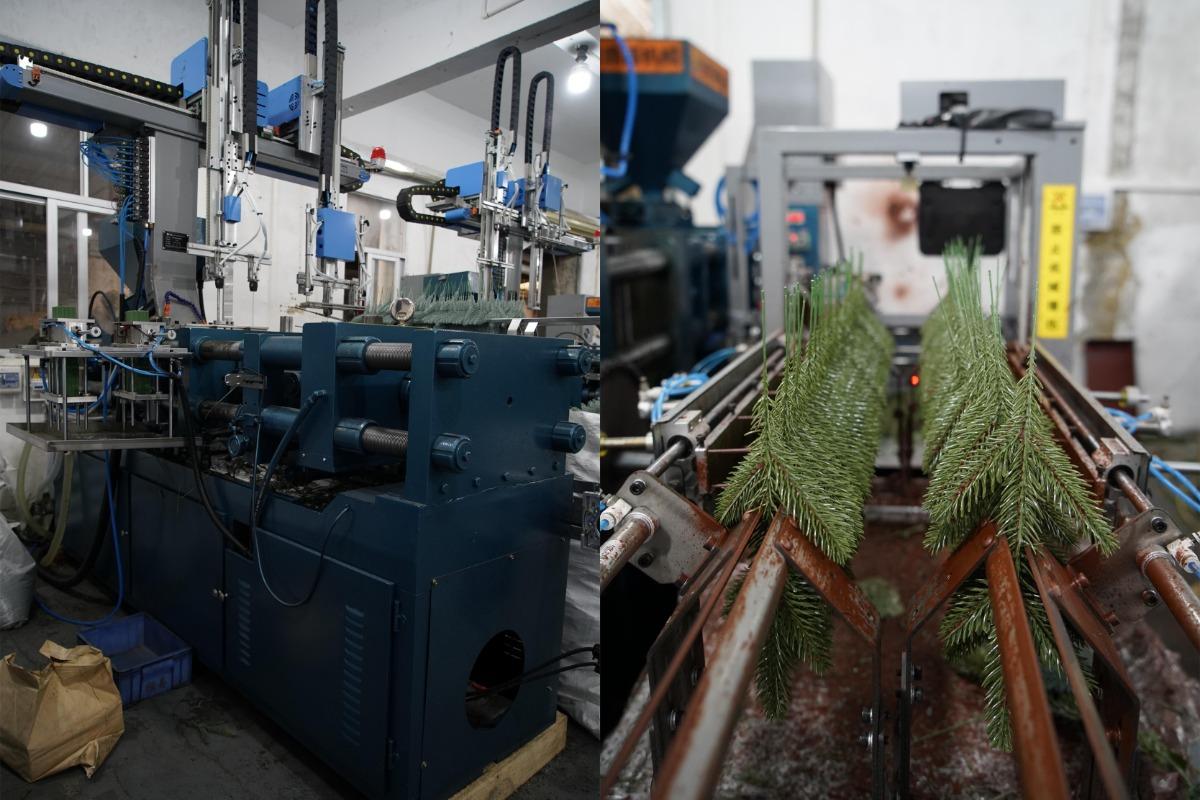

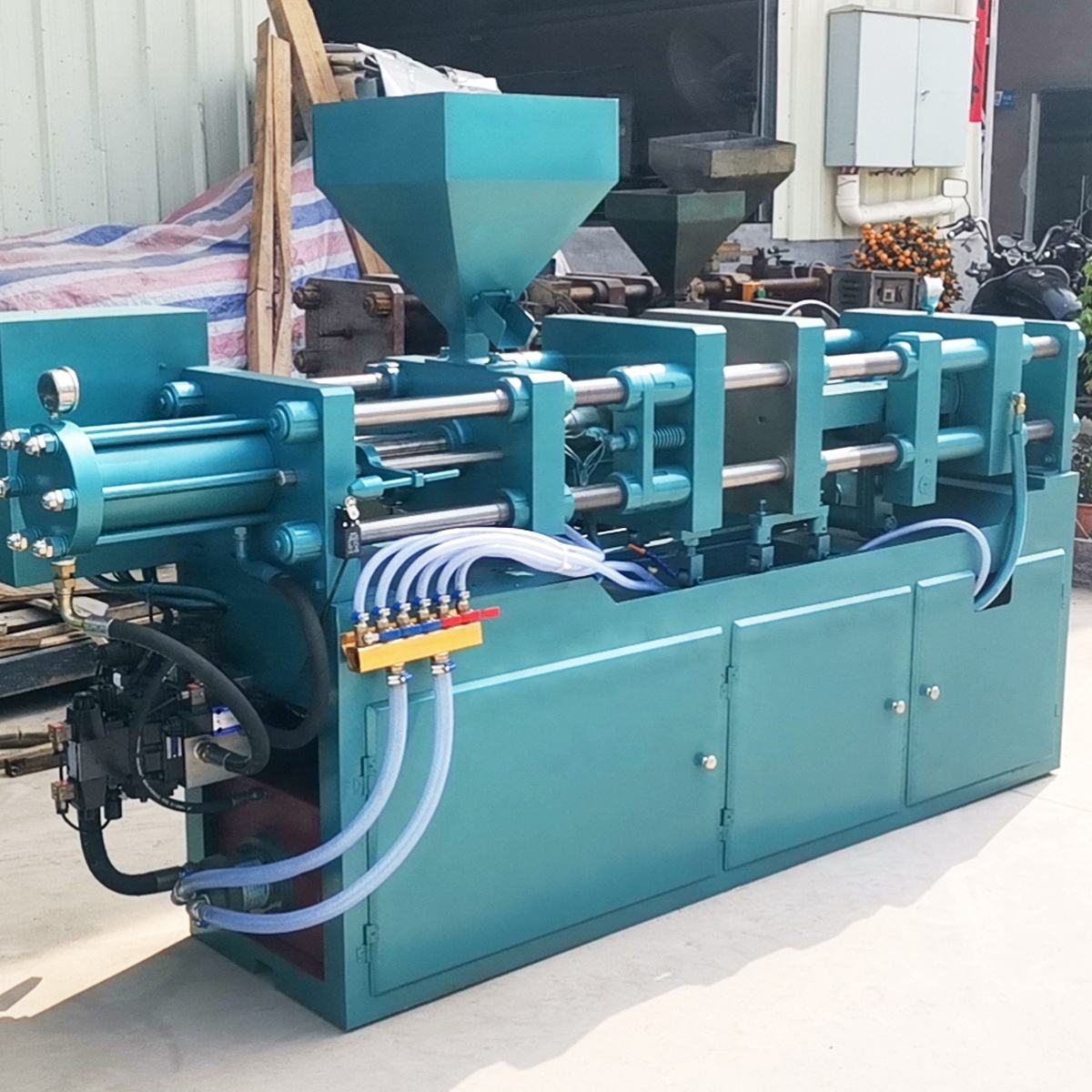

Our PE injection molding machines are commonly used for producing PE artificial Christmas tree leaves. These machines can produce two-tone PE Christmas tree leaves in a single cycle, and the servo motor significantly reduces your electricity consumption. This machine is electric and is used with PE injection molds.

PE Injection Molding Machine Parameter

| Pump Core Diameter(S2.5A/T2.5A/T3.5A) | 38mm/28mm/28mm |

| Pump Core Length(S2.5A/T2.5A/T3.5A) | 290mm/290mm/350mm |

| Injection Volume(S2.5A/T2.5A/T3.5A) | Single-color 32g/Two-color 28g/Two-color 30-32g |

| Injection Pressure(S2.5A/T2.5A/T3.5A) | 2100psi |

| Mold Damping Force(S2.5A/T2.5A/T3.5A) | 1200psi/1200psi/1500psi |

| Mold Moving Stroke(S2.5A/T2.5A/T3.5A) | 215mm |

| Maximum Mold Thickness(S2.5A/T2.5A/T3.5A) | 215mm/280mm/280mm |

| Maximum Mold Width(S2.5A/T2.5A/T3.5A) | 215mm/400mm/450mm |

| Minimum Mold Width(S2.5A/T2.5A/T3.5A) | 100mm/100mm/200mm |

| Maximum Oil Pump Pressure(S2.5A/T2.5A/T3.5A) | 2500psi |

| Motor Power(S2.5A/T2.5A/T3.5A) | 7.5kw |

| Electric Heating Power(S2.5A/T2.5A/T3.5A) | single color-3.2kw/two color-3.6kw/two color-5.4kw |

| Weight(S2.5A/T2.5A/T3.5A) | 1800kg/1800kg/2070kg |

Advantages Of PE Injection Machine

Energy saving

PE injection molding machines equipped with servo motors can achieve significant energy savings, which can generate substantial profits, especially in areas with high electricity costs.

High Efficiency

This PE injection molding machine can produce two-color PE Christmas tree leaves in a single injection, improving production efficiency and making the entire production process faster.

Automation

This machine is typically used in conjunction with a robotic arm, which automates the entire production of PE Christmas tree leaves. Workers only need to put in and remove the leaves.

Application Of PE Injection Molding Machine

In the production of artificial Christmas trees, PE injection molding machines are specifically designed for the production of PE Christmas tree leaves. Typically, PE injection molding machines are used in conjunction with robotic arms and PE injection molds as a PE leaf injection system. The entire system operates automatically, enabling rapid production of PE Christmas tree leaves.

Compared to PVC Christmas tree leaves, PE injection molding machines produce injection-molded leaves that are visually very realistic, making them ideal for binding high-quality artificial Christmas trees.

Packaging And Shipping

Packaging

Generally, we use wooden crates to pack the machines. We place pallets at the bottom of the crates for easy transport, and reinforce the bottom inside the crates with wooden boards to secure the machine. We also include some easily damaged parts inside the crates to ensure long-term machine use.Of course, if you have special packaging requirements, we can also customize packaging for you.

Shipping

The machine supports both air and rail transport; you can choose the delivery method that best suits your needs. We will notify the factory to begin production upon order confirmation. After completion, the machine will be tested, and once confirmed to be working correctly, it will be packed and delivered to the designated location. If you have a local agent in your area, we can also deliver the machine to them, who will handle the remaining shipping procedures.

FAQ

What is this PE injection molding machine mainly used for?

This PE injection molding machine is specially designed for producing PE artificial Christmas tree leaves. It works with PE injection molds and robotic arms to form a fully automatic PE leaf injection system, suitable for high-end artificial Christmas tree manufacturing.

Can this machine produce two-color PE Christmas tree leaves?

Yes.

This machine supports double-color (two-tone) PE injection, allowing realistic color transitions in a single injection cycle, which greatly improves the appearance of PE Christmas tree leaves compared to single-color injection.

What models are available for this PE injection molding machine?

This machine is available in 2.5A / 3.5A double color models.

Each model differs in injection volume, mold size compatibility, and output capacity. We can recommend the most suitable model based on your PE leaf size and production requirements.

What materials can be used with this injection molding machine?

The machine is designed for PE (Polyethylene) materials only.

It is not suitable for PVC or PET materials, as PE injection molding requires a different heating, pressure, and mold system.

Does the machine support automatic production?

Yes.

This PE injection molding machine is commonly used together with robotic arms, enabling automatic leaf removal and continuous production. Workers only need to load materials and monitor operation, significantly reducing labor costs.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá