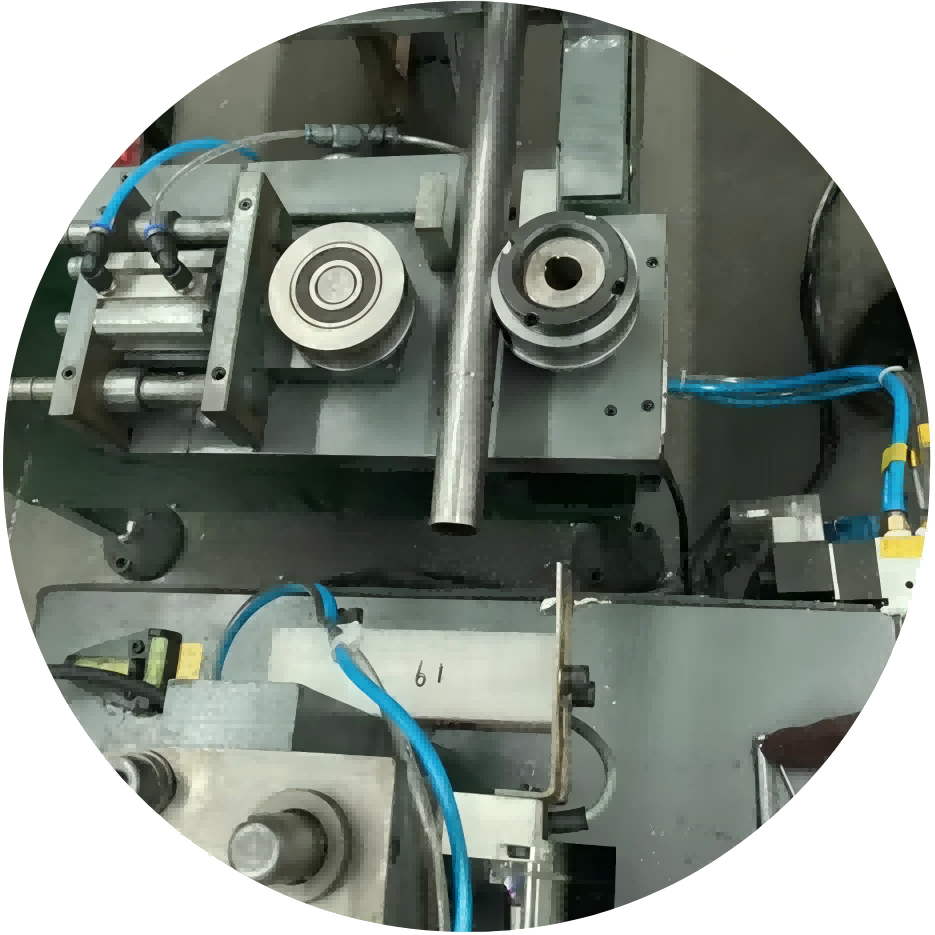

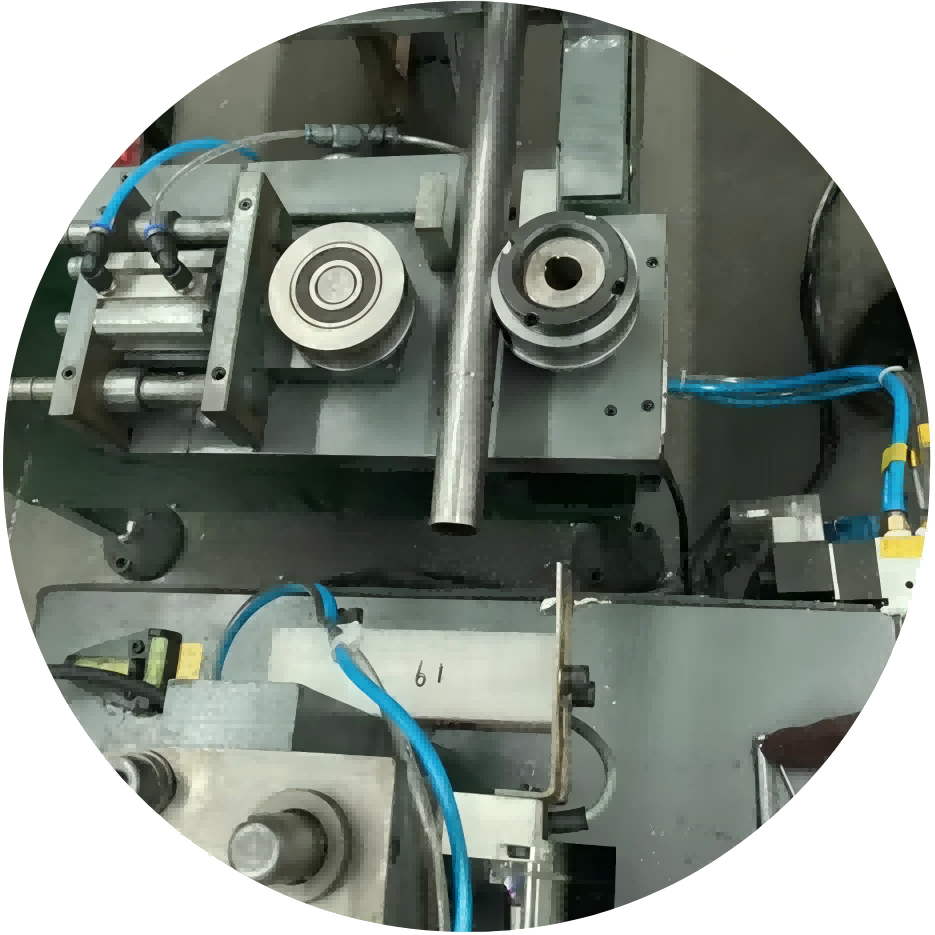

Automatic loading and rolling pipe cutting machines can quickly process placed metal pipes, and while ensuring processing speed, can control the error of each processed iron pipe to a very small degree.In the production of artificial Christmas trees, this machine mainly plays an auxiliary role, providing iron pipes for welding the base of the artificial Christmas tree, and is a part of the complete independent artificial Christmas tree production system.

Application Of Pipe Cutting Machine

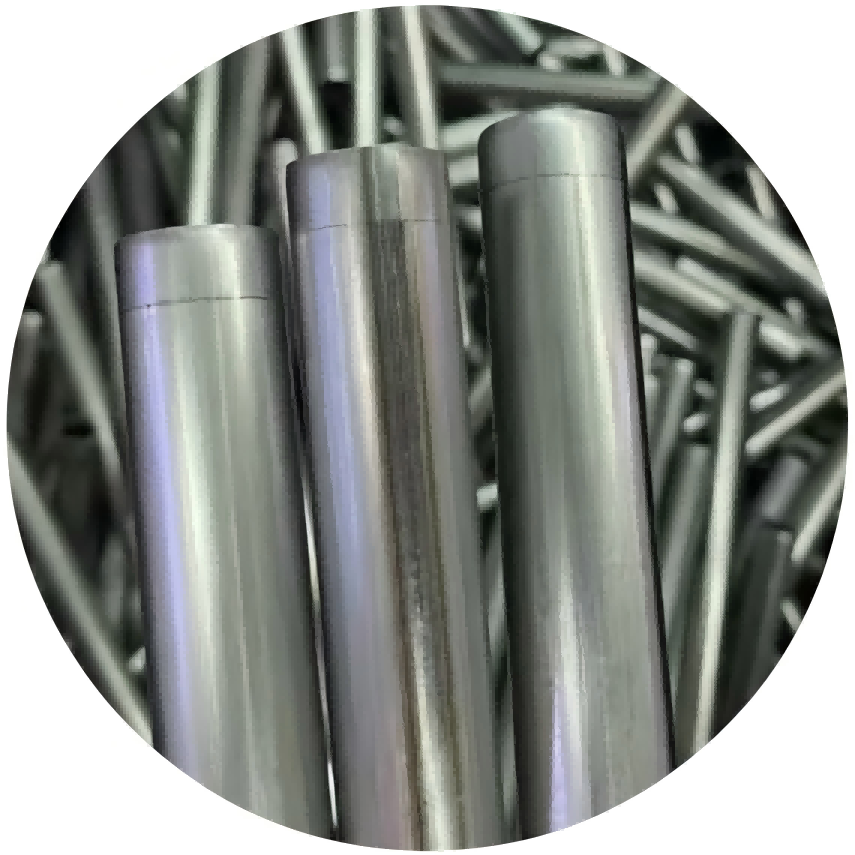

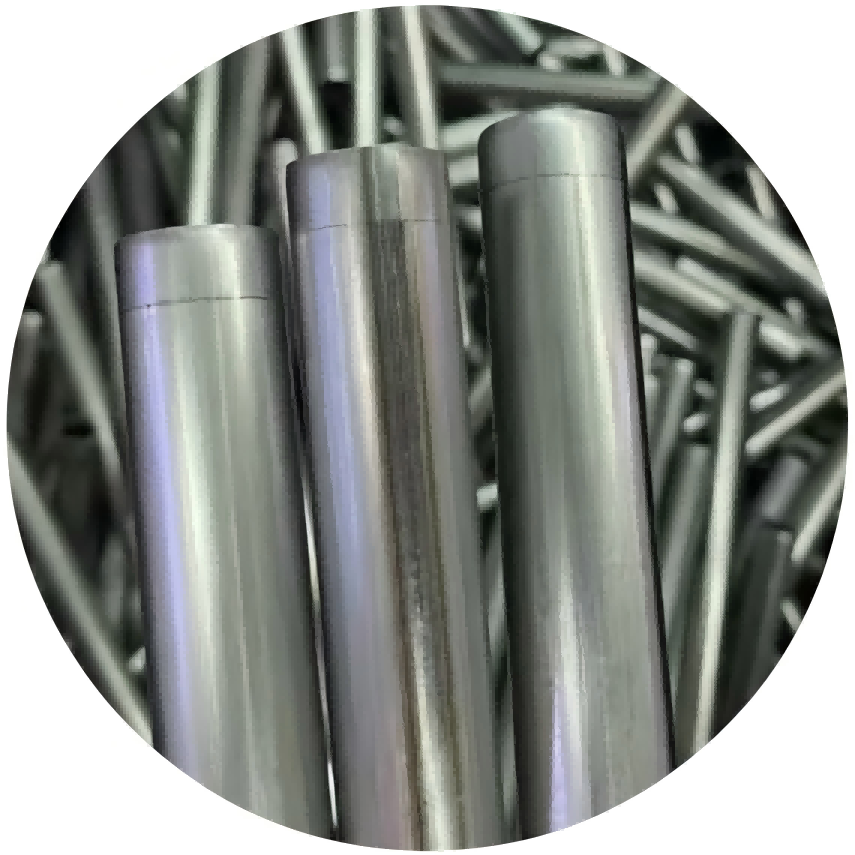

In the production of artificial Christmas trees, this machine primarily provides the iron pipes needed for welding the base of the tree. The machine’s 6-25mm iron pipe cutting range can cover the four small legs of the artificial Christmas tree base as well as the central trunk iron pipe.

After the iron pipes for the tree base are cut, bent by a machine, and welded by a welding arm, the base of the artificial Christmas tree is initially completed.Next, we will apply a surface paint finish to these artificial Christmas tree metal feets, shaping them as shown in the image on the right. We typically choose dark green as the color for the tree feets.

Pipe Cutting Machine Parameter

| Cut Diameter Range | 6-25mm |

| Cut Length | 20-1000mm |

| Cutting Wall Thickness | 0.2-2mm |

| Motor | Servo Motor, Three-Phase Power |

| Power Of Motor | 0.75KW |

| Roll-Cut Saw Blade | Diameter 100* Inner Hole 27 Wall Thickness 1.0mm |

| Material Of Roll-Cut Saw Blade | Tungsten Steel |

| Device Dimensions | 7500*500*750mm |

| Equipment weight | 400kg |

Advantages Of Pipe Cutting Machine

Supports multiple pipe

This machine can accommodate most steel pipe diameters, and it can cut steel pipes with diameters ranging from 6 to 25 mm and wall thicknesses ranging from 0.2 to 2 mm.

High-Efficiency Cutting

The machine has a very high production efficiency, typically processing a section of placed steel pipe in about 2 seconds. This machine can process approximately 15 meters of iron pipe per minute.

High-Precision Cutting

The steel pipes cut by the automatic loading and rolling machine have very small errors in precision, usually controlled to around ±0.5mm, so you don’t need to do secondary processing.

Packaging And Shipping

We typically use wooden crates to pack the machines, and then wrap the machine parts with plastic film to prevent potential moisture damage. Small wooden blocks are placed at the bottom of the inside of the crate to secure the machine, and plastic straps are used for binding to ensure the machine doesn’t tilt or fall during transport.If you have any specific packaging requirements, please contact us to discuss them.

We typically place some easily damaged parts in the machine’s wooden crate to prevent wear and tear from prolonged operation, but these parts may be difficult to purchase locally. Of course, please feel free to contact us if you encounter any further issues regarding spare parts.

FAQ

This machine cuts which types of iron pipes?

It is designed for cutting and rolling metal pipes used for artificial Christmas tree bases and trunk connectors. It supports pipe diameters from 6–25mm and pipe lengths from 20–1000mm.

Is the machine fully automatic?

Yes. The machine automatically handles pipe loading, feeding, cutting, and rolling, requiring only minimal supervision from the operator.

What is the cutting accuracy of this machine?

The cutting error is within ±0.2–0.5mm, ensuring consistent size for Christmas tree legs and base pipes.

What is the production speed?

It processes around 6 meters of iron pipe per minute, equivalent to cutting a piece of steel pipe every 1.8–2 seconds.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá