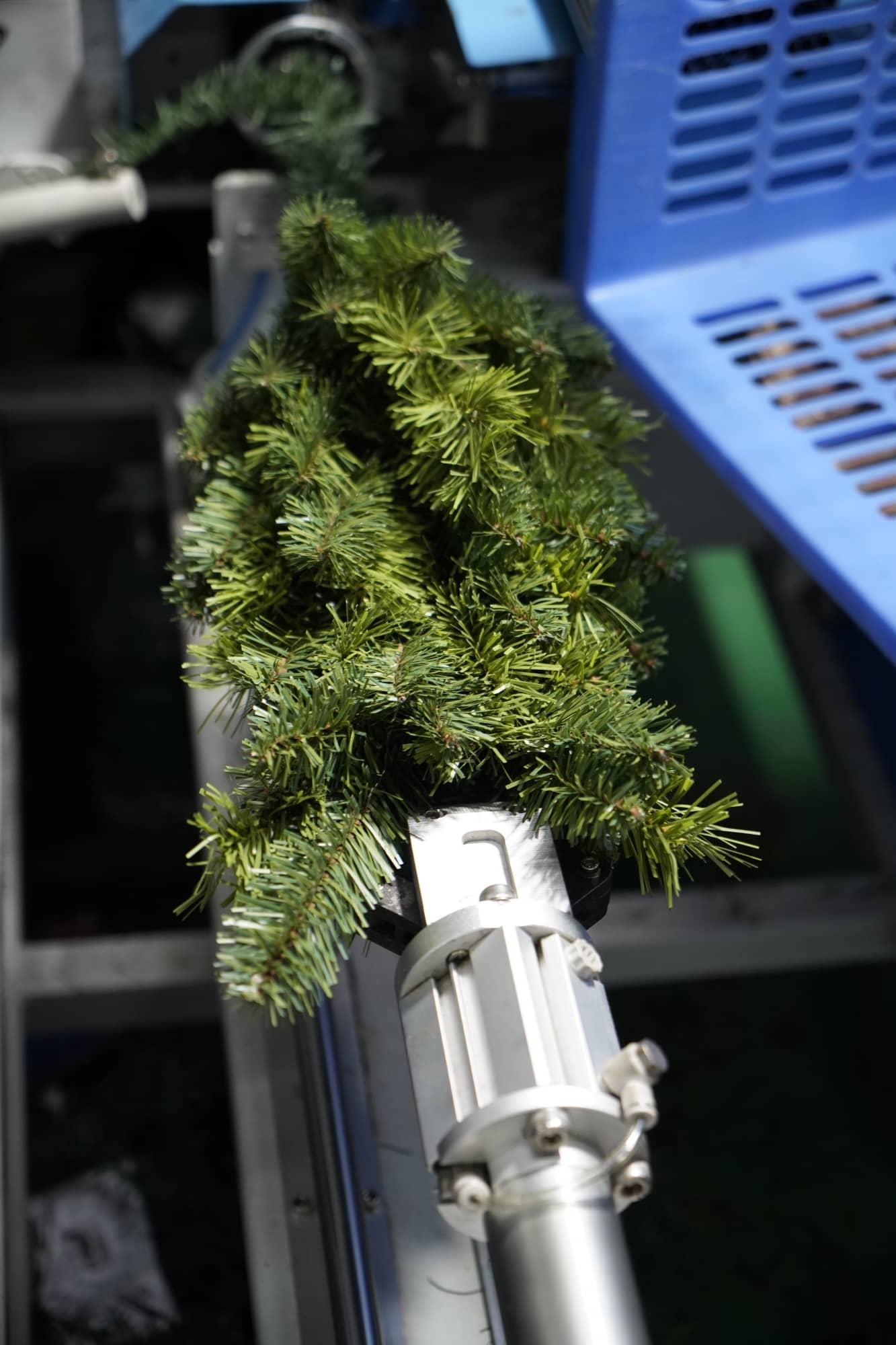

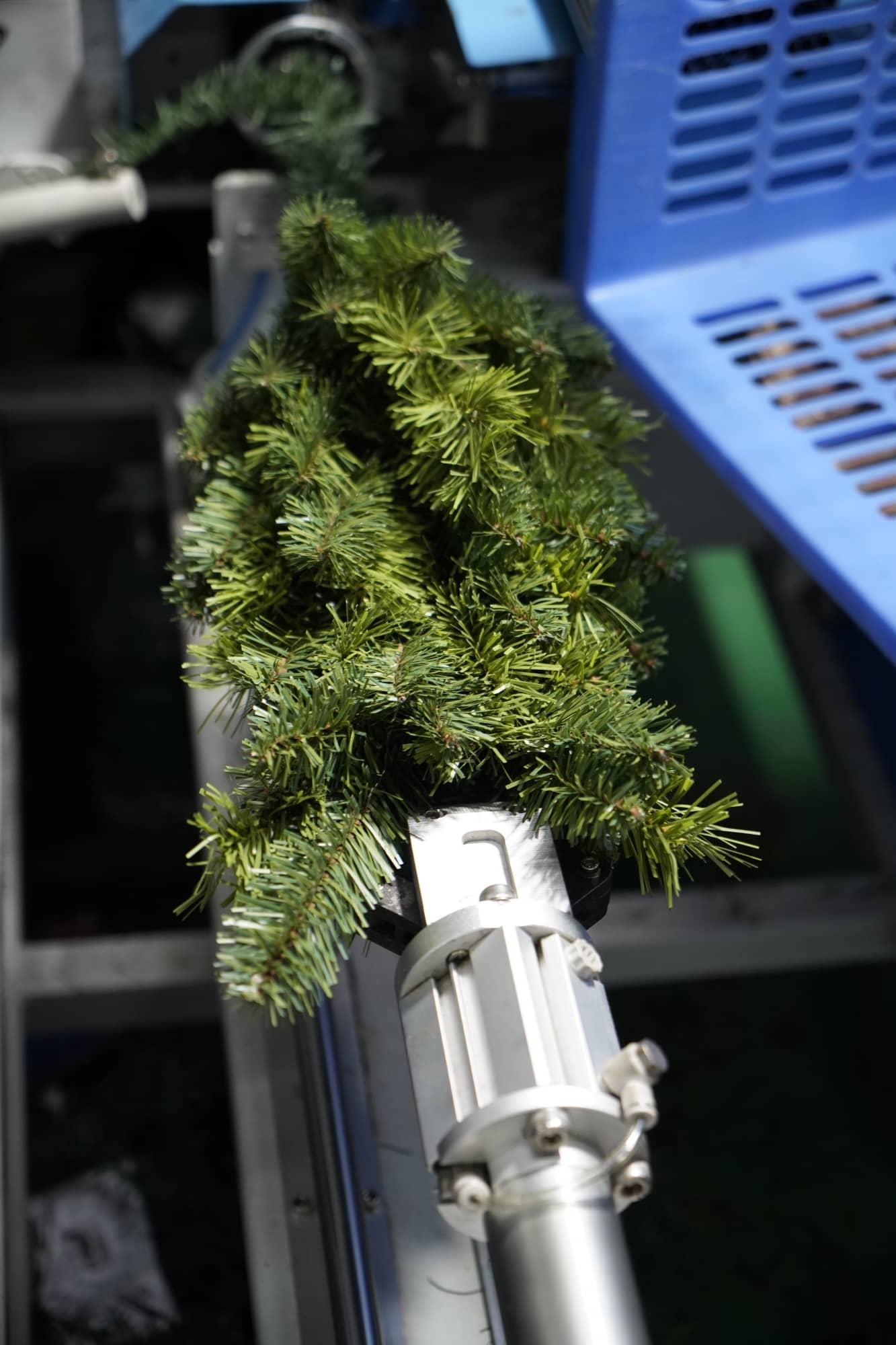

The artificial Christmas tree head branch binding machine is a common piece of machinery used in the production of both PVC and PE Christmas trees. It is primarily used for binding the top of artificial Christmas trees and for binding branches to the trunk sections that do not use tree hubs.The artificial Christmas tree head branch binding machine is operated via a control panel, which allows you to determine the spacing between the branches, the wrapping speed, and the melting time. You can adjust these settings to meet the specific needs of producing your desired Christmas trees.

Tree Head Binding Machine Parameter

| Device Name | Tree Head Branch Binding Machine |

| Overall Dimension | 2450mm*620mm*1120mm |

| Package Size | 2300mm*640mm*1120mm |

| Rated Voltage | 220V |

| Rated Power | About 1900W |

| Applicable Steel Pipe/Wire | 4-22mm Steel Pipe/Wire |

| Product Suitable For | Christmas tree head branchbinding production.The straight

steel pipe or wire is in 1-20 segments 150-900 mm long and

4-32 mm in diameter. |

| Designed Speed | 10000-40000 Leaves/Day |

| Number Of Binding Segments | Segment 1-20 |

| Thread Finish | Ultrasonic Wave(Optional) |

| Automatic segmental binding, segment 1-20. |

| Automatic end knotting(optional),nosmoke,no smell,no heating. |

| Computer intelligent control, accurate, energy saving. |

| Touch the screen for man-machine dialogue in Chinese, set parameters and monitor the equipment running status. |

| One key start and stop, automatic fault detection, automatic alarm and stop. |

Tree Head Binding Machine Advatages

Automation

The artificial Christmas tree head branch binding machine can automatically perform segmented branch binding and complete tasks such as automatic end knotting.

Multilingual

This machine features multilingual localization and can be customized to your needs. Please inform us of your requirements for customization before ordering.

Widely Applicable

This machine can meet the needs of binding the tops of PE and PVC Christmas trees, and can also meet the needs of binding the trunks of artificial Christmas trees.

Machine Application For Artificial Christmas Tree Production

In the production of artificial Christmas trees, binding branches is an essential step, and this artificial Christmas tree head branch binding machine is used in both PVC and PE Christmas tree production. Besides binding the top of the artificial Christmas tree, this machine can also be used to tie branches to the trunk if the tree is not secured with tree hubs and hollow rivets.This method of binding artificial Christmas trees allows you to manually adjust how tightly the branches are gathered.

· It can be used to bind the top of the artificial Christmas tree.

· It can support part of the Christmas tree trunk for binding.

Compared to traditional manual bandaging machines, this machine significantly reduces operator time for individual steps and streamlines the entire process, ensuring consistent intervals between each bandage.

Packaging and Shipping

Packaging

Generally, we use wooden crates to pack the machines. We place pallets at the bottom of the crates for easy transport, and reinforce the bottom inside the crates with wooden boards to secure the machine. We also include some easily damaged parts inside the crates to ensure long-term machine use.Of course, if you have special packaging requirements, we can also customize packaging for you.

Shipping

The machine supports both air and rail transport; you can choose the delivery method that best suits your needs. We will notify the factory to begin production upon order confirmation. After completion, the machine will be tested, and once confirmed to be working correctly, it will be packed and delivered to the designated location. If you have a local agent in your area, we can also deliver the machine to them, who will handle the remaining shipping procedures.

FAQ

What is a tree head branch binding machine used for?

A tree head branch binding machine is used to bind the top section of artificial Christmas trees, especially the head and trunk area where branches are gathered closely.

It is designed for trees without tree hubs, allowing flexible adjustment of branch spacing and tightness.

What is the difference between a tree head binding machine and a normal branch binding machine?

The main differences are:

Designed specifically for top and trunk sections

Supports shorter binding lengths and multiple segments

Allows manual control of binding density

Better suited for trees without hubs or hollow rivets

Standard branch binding machines are mainly used for regular branch production, not precise head binding.

Is this machine suitable for both PVC and PE artificial Christmas trees?

Yes.

This machine is widely used in both PVC and PE artificial Christmas tree production lines, especially during the final assembly stage.

What wire or pipe sizes can this machine handle?

This machine supports:

Steel pipe or wire diameter: 4–32 mm

Binding segments: 1–20 segments

Segment length: 150–900 mm

This makes it suitable for various tree sizes and structures.

How many trees can this machine produce per day?

The designed capacity is approximately 10,000–40,000 leaves/day, depending on:

Tree structure

Binding segment settings

Operator experience

Our team can help calculate output based on your production goals.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Bahasa Indonesia

magyar

Română

Čeština

Монгол

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Norsk

Svenska

Suomi

Dansk

اردو

বাংলা

සිංහල

Беларуская мова

Български

Hausa

Igbo

Basa Jawa

ಕನ್ನಡ

മലയാളം

Afaan Oromoo

ਪੰਜਾਬੀ

Soomaali

Basa Sunda

తెలుగు

संस्कृत

Yorùbá